Colorado is home to a multitude of plastic injection molding companies, catering to various industries with their expertise and capabilities.

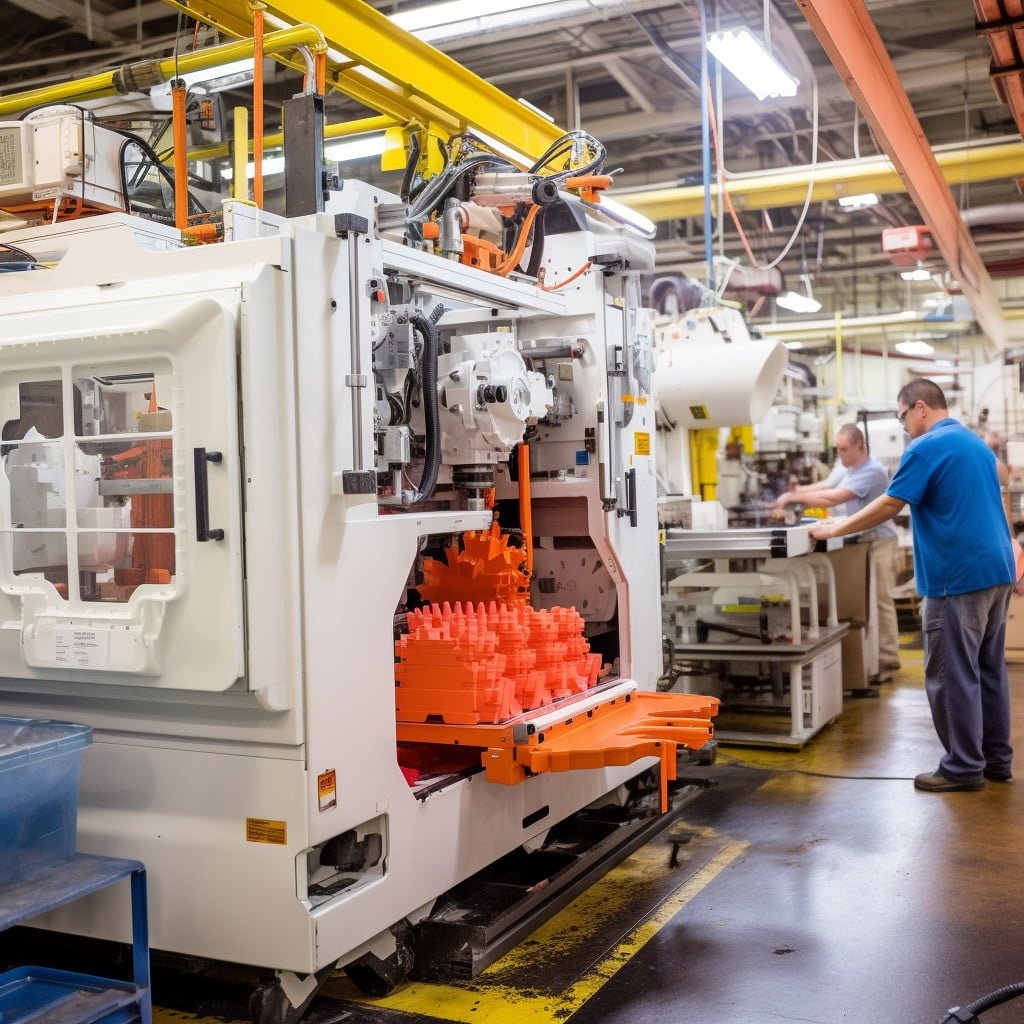

Plastic injection molding has become a crucial manufacturing process across various industries, and Colorado is home to an array of reputable companies specializing in this field. With their advanced technology, skilled workforce, and commitment to quality, these injection molding companies in Colorado have established themselves as leaders in the industry.

In this blog post, we will delve into the top plastic injection molding companies in Colorado, exploring their capabilities, expertise, and the reasons why they are trusted partners for businesses seeking precision-engineered plastic components. Whether you’re a local entrepreneur or nationwide manufacturer looking for reliable injection molding services in Colorado, read on to discover the key players that can bring your ideas to life with efficiency and excellence.

VS Molding

Contact phone: (303) 833-5810

Services:

- Custom injection molding services for thermoplastic products

- Fabrication services for tooling used in injection molding

- Engineering support to ensure timely and cost-effective product development

- Short run production from 1,000 to 100,000 pieces

- Insert molding, prototype, and production tooling with domestic and offshore suppliers

V&S Molding is a respected thermoplastic injection molding company. With expertise in custom injection molding, they cater to various industries, such as aerospace, medical, telecommunications, and lighting.

In addition to their molding services, V&S Molding provides tooling fabrication and engineering support to ensure efficient product development for their customers. Their commitment to quality and timely delivery has established them as a trusted partner since 1982.

Caroba Plastics

Facebook page: Facebook

Services:

- Stock programs for medical and semi-conductor markets

- Custom assembly solutions for manufacturing and supply chain needs

- In-house mold making, repair, and maintenance facility

- Complete manufacturing package including design assistance, manufacturing, and shipping/fulfillment

- Strong thermoplastic technical support and expertise from project start-up

Caroba Plastics is a leading injection molding company in the Rocky Mountain region, specializing in order fulfillment, custom assembly, and insert molding. With certification to stock programs for both medical and semi-conductor markets, Caroba provides a comprehensive manufacturing package that includes design assistance, engineering expertise, and shipping/fulfillment services.

Their dedicated project teams of engineers and molding professionals ensure strong thermoplastic technical support throughout every stage of production to optimize efficiency and cost-effectiveness for their customers.

Sovereign Plastics

Contact phone: (254) 535-2419

Facebook page: Facebook

Services:

- Design services

- Tooling services

- Production services

- Shipping services

- Prototyping services

Sovereign Plastics is an injection molding company that places emphasis on structured processes to consistently deliver high quality parts. With their own facility in Colorado, they have a highly skilled team that builds over 100 molds per year using state-of-the-art equipment and proprietary software.

They use a high-grade metal alloy for their molds and offer maintenance and repair services, guaranteeing the molds for the life of the project as long as they are molding the parts.

PTA Plastics

Contact phone: (203) 888-0585

Services:

- New product introduction and speed to market

- Engineering for low/medium volume and high mix solutions

- Deep moldmaking competencies

- Specialization in the medical, defense, and safety and security markets

- State-of-the-art technology and an accomplished team for a trusted and dependable experience

PTA Plastics is an injection molding company specializing in engineering solutions for low/medium volume and high mix products. With a focus on the medical, defense, and safety and security markets, they leverage state-of-the-art technology and their experienced team to provide trusted and dependable manufacturing experiences.

As an Employee-Owned company with over 70+ years of experience since 1953, PTA Plastics offers innovative custom injection molding solutions while maintaining the highest standards of quality.

Intertech Plastics

Contact phone: (309) 664-7394

Services:

- Custom injection molds for medical, industrial, and consumer parts and packaging

- Engineering injection mold prototypes with advanced technology and problem-solving approach

- Utilizing process controls and automated quality compliance systems

- Fully automated production lines monitored by innovative vision systems

- Efficient automation with plastic molding technology

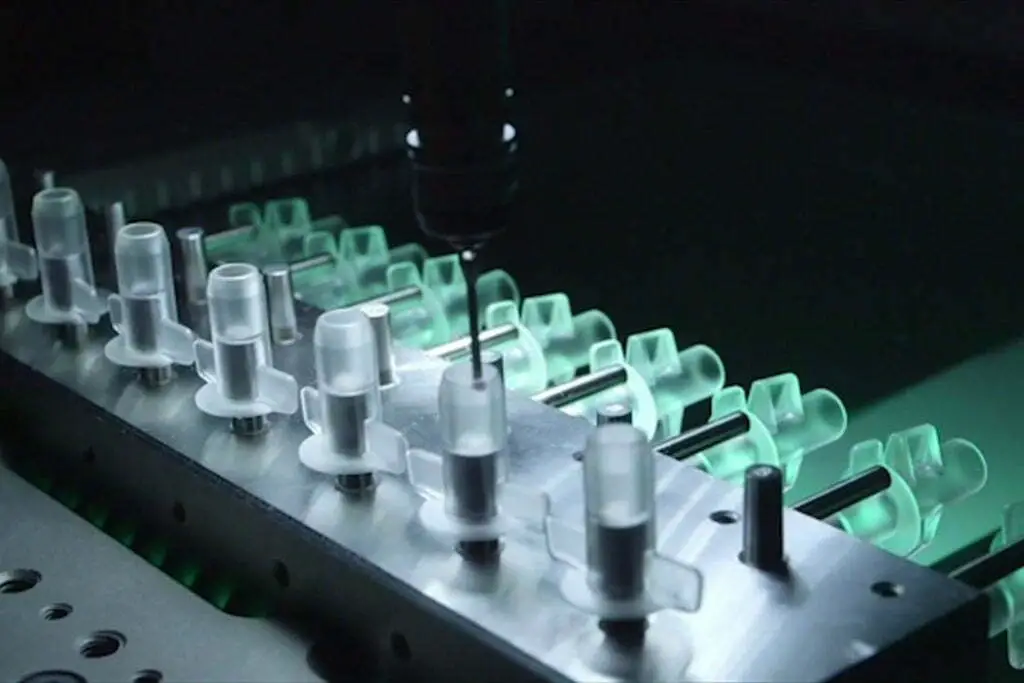

Intertech Plastics, an award-winning injection molding company based in Denver, Colorado, specializes in creating custom injection molds and precision plastics for medical, industrial, and consumer parts and packaging. With over 40 years of experience and a commitment to advanced manufacturing innovations, they deliver zero-defect solutions using efficient automation and cutting-edge technology.

From engineering injection mold prototypes to ensuring automated quality compliance systems, Intertech is dedicated to providing top-notch products that meet the highest industry standards.

Xometry

Facebook page: Facebook

Services:

- Highly customized on-demand prototype and production molding

- Expert consultation on each injection mold quote

- Project managers on every order to move parts from design to production

- Experience across industries, including medical, automotive, aerospace, consumer goods, and more

- Assurance of part quality with ISO 9001:2015 and AS9100D certified quality management system, ITAR registration, and options for inspections, hardware traceability, material certifications, and CoCs

Xometry injection molding is a leading provider of highly customized injection molding services for Denver, Colorado. With a customer-first approach, their skilled engineering team ensures that each step of the molding process is guided with expertise and precision.

Their extensive experience across various industries, coupled with certifications and quality assurance measures, guarantees the delivery of high-quality plastic prototypes and production parts on time and at competitive prices.

AIM Processing

Services:

- Focus on small plastic parts for greater efficiency, lower costs, and improved manufacturability

- Mechanical engineering team to vet designs for quality and cost optimization

- Employment of experienced plastics professionals for over 25 years

- ISO 9001 registered with rigorous inspections from over 100 customers

- Customer-centric approach with on-site engineers, 24/7 operation, and meeting deadlines

This injection molding company specializes in small plastic parts, offering improved efficiency, cost-effectiveness and manufacturability. With over 2000 successfully produced parts, their team of mechanical engineers assists in design vetting to optimize quality and reduce costs.

Backed by an experienced staff and ISO 9001 registration, they deliver competitive pricing and ensure customer expectations are met.

LTM Plastics

Services:

- Consistent part quality ensured by cutting-edge systems and expert staff

- Streamlined process through secondary operations such as over-molding, assembly, and packaging

- On-time delivery with US-based manufacturing

- Facilitation of transfer tooling to ensure smooth operations for clients

- Ideal fit for growing companies looking to launch new product lines or stabilize their supply chain

LTM Plastics is a leading injection molding company that specializes in delivering consistent part quality through cutting-edge systems and a skilled team. With expertise in secondary operations such as over-molding, assembly, and packaging, they can streamline the entire manufacturing process.

Offering on-time delivery and the ability to facilitate seamless tooling transfers, LTM Plastics is an ideal partner for growing companies looking to launch new product lines or stabilize their supply chain. They prioritize continuous improvement by reinvesting in their team, tools, and technology to stay ahead of industry changes and ensure maximum efficiency.

Colorado Molded Products Company (CMPC)

Contact phone: (800) 875-5805

Services:

- Product design guidance

- Engineering support

- Prototyping services

- Manufacturing process expertise

- Elastomer selection assistance

Colorado Molded Products Company (CMPC) is a leading injection molding company with over 75 years of experience in manufacturing custom molded rubber products. They specialize in product design, engineering, prototyping, and manufacturing processes.

With a wide range of presses and the ability to accommodate molds up to 30″ x 40″, CMPC is equipped to handle complex projects and tight delivery schedules. Customers can trust CMPC to provide high-quality solutions tailored to their specific needs.

Contact them today for an estimate.

Moldrite Products, Inc

Company: moldriteproducts.com

Contact phone: (719) 573-9305

Services:

- Precision planning and listening to the customer

- Innovative engineering to solve problems

- Reliable delivery within budget and on time

- Comprehensive molding and production services

- Consulting services to ensure product meets specifications and quality control measures

Moldrite Products, Inc. Is an innovative market leader in plastics injection molding based in Colorado Springs, Colorado.

With a focus on precision planning and innovative engineering, we have the expertise and technologies to deliver high-quality plastic molding products that meet your exact specifications. Our reliable delivery ensures on-budget and on-time completion, while our comprehensive services encompass all aspects of molding from conception to construction and production.

With exclusive use of Milacron machines, we guarantee top-notch quality for every project.

Tenere Inc

Facebook page: Facebook

Services:

- Plastic injection molding

- Contract manufacturing

- Prototyping

- Tooling and mold design

- Assembly and finishing services

Tenere Inc. Is a reputable contract manufacturer based in Westminster, CO, specializing in plastic injection molding services.

With an established operation, they provide efficient and high-quality manufacturing solutions to their clients.

WP Manufacturing

Company: wpmfg.com

Contact phone: (303) 772-1325

Services:

- Plastic Injection Molding

- Precision Machining

- Tooling

- Pad Printing

- Assembly & Packaging

WP Manufacturing, founded in 1970, is a contract manufacturer specializing in Plastic Injection Molding, Precision Machining, Tooling, Pad Printing, and Assembly & Packaging. Their services include insert and over molding, clean room molding, metal to plastic redesigning, secondary assembly and packaging such as milling, drilling, tapping, routing.

This company also provides precision machining for metals and plastics including production and prototype machining with 5 axis and Swiss screw capabilities. Additionally they offer tooling services for short or long production runs using plastics or metals with tool steel or aluminum tooling options.

Natech Plastics

Contact phone: (631) 580-3506

Services:

- Engineering services

- Custom injection molding

- Contract manufacturing services

- Manufacturing of medical components and devices

- High-speed automation with servo-driven robotics

Natech Plastics stands as the industry leader among medical plastic injection molding companies. As an ISO-certified, family-owned entity, they offer top-notch engineering, custom injection molding, and contract manufacturing services.

With a commitment to meeting demanding applications through expert engineers and manufacturers, their focus on high-volume production makes them a suitable choice for medical device manufacture. Proudly operating in the USA with tools and production parts made domestically, Natech utilizes servo-driven robotics for efficient automation across all their injection molding presses.

Superior Plastics

Facebook page: Facebook

Services:

- Plastic mold building services

- Plastic injection molding services

- Drop shipping and private labeling for plastic injection molds

- Manufacturing with a range of injection molding machines, including Cincinnati, Van Dorn, Toyo, Arburg, and Milacron

- Specialization in plastic injection molding for aircraft instruments

This injection molding company has over 39 years of experience in the custom plastic injection molding industry. They specialize in providing precision, speed, and efficiency in bringing designs to life.

They serve a variety of industries including aircraft instruments, aerospace, construction, electronics, industrial, military, oil field, and telecommunications.

Peak Fulfillment

Facebook page: Facebook

Services:

- Streamlined manufacturing and injection molding

- Mass production manufacturing for regional and local businesses

- Complex manufacturing capabilities to enhance productivity and profitability

- Sophisticated machinery and flexible techniques for high-quality manufacturing

- Full-service thermoplastic injection molding for various industries

Peak Manufacturing and Fulfillment is the leading injection molding company in the Rocky Mountain Area, specializing in efficient and high-quality product manufacturing. With a stacked lineup of state-of-the-art machinery and a zero waste philosophy, they provide complex manufacturing capabilities that enhance productivity and profitability.

Their modern techniques, professional personnel, and advanced robotics technology optimize the manufacturing process for faster production times and higher yield rates.

The Rodon Group®

Company: rodongroup.com

Facebook page: Facebook

Services:

- Plastic Injection Molding

- Custom Plastic Injection Molding

- Standard Parts

- Parts Gallery

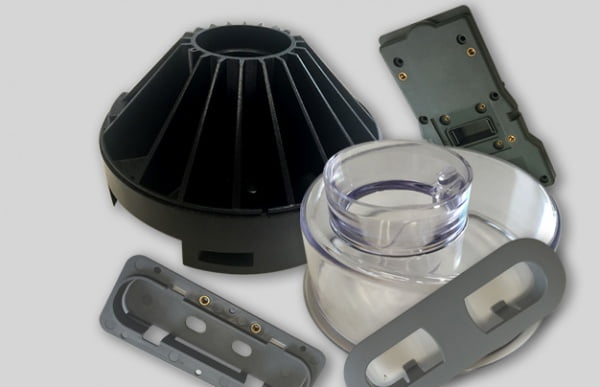

- Varying materials and surface finishes for custom injection molding

The injection molding company specializes in custom plastic injection molding, offering a variety of materials suited for different applications. They provide options such as Acrylonitrile Butadiene Styrene (ABS), Low-Density and High-Density Polyethylene (LDPE and HDPE), Polycarbonate (PC), Polyamide (Nylon), High Impact Polystyrene (HIPS) and Polypropylene (PP).

Whether you need flexible, lightweight parts with good impact strength and durability, transparent alternatives to glass, electrical properties with resistance to heat and chemicals, non-toxic components for food-grade applications, or robust plastics with high melting points, this company can deliver the suitable material for your custom injection molded parts.

ALBA

Services:

- Comprehensive guidance for application needs, including DFM, tooling, thermodynamics, advance simulation, and machine and auxiliary selection

- Project management from part inception to final production cell delivery and installation

- Distribution of Cronoplast SL’s Babyplast micro injection molding machines

- Distribution of Vega srl mold hydraulic cylinders

- Distribution of Alba-brand Quick Knockout Couplers and Alba-developed peripherals and mold components

ALBA Enterprises, LLC is a leading injection molding company based in Loveland, Colorado. With their new facility equipped with advanced technology and a team of skilled workers, they offer comprehensive solutions for micro-molding applications.

From designing and building molds to providing project management services, ALBA Enterprises ensures efficient and high-quality production for their clients.

Cadrex

Facebook page: Facebook

Services:

- Expertise in complex product design and engineering involvement

- Mitigation of product design issues and costs during the NPI process

- Experience with temperamental specialty materials and intricate tool builds

- Dedicated team of experts serving as a single point of contact throughout the product lifecycle

- Wide range of injection molding capabilities, including overmolding, structural foam molding, insert molding, and post-mold machining

With expertise spanning over 50 years in the industry, this injection molding company delivers comprehensive capabilities and specialized solutions for complex product designs. Their dedicated team of experts provides personalized assistance throughout the entire product lifecycle, from initial parts discussions to production launch.

Offering a range of services including plastic and metal overmolding, structural foam molding, insert molding, automation systems, post-mold machining, and in-house tool design and maintenance, they are equipped to meet various manufacturing requirements.

ARC Group Worldwide

Company: arcw.com

Services:

- Metal Injection Molding (MIM)

- MIM School

- Design For MIM

- MIM Properties

- Fully Customizable

The injection molding company, ARC Leadership, is a leading provider of metal injection molding (MIM) technology. With a strong focus on aerospace, automotive, defense, and medical industries, they offer cutting-edge capabilities and exceptional quality.

Their team of industry experts ensures that their products meet the highest standards and are fully customizable to meet their clients’ specific needs. They have multiple locations and provide efficient customer service with quick quote requests.

Parkway Products, LLC

Company: parkwayproducts.com

Contact phone: (774) 862-7380

Services:

- Advanced Material Solutions

- Machined Plastic Solutions

- Magnesium Thixomolding

- High Performance Polymer Molding

- Thermoset Molding

Parkway Injection Molding, based in Loveland, Colorado, offers Magnesium Thixomolding as one of its advanced material solutions. This specialized process utilizes magnesium alloy ingot chips to manufacture parts with unique properties not achievable with traditional die cast or injection molded parts.

By combining the benefits of die casting and injection molding, Magnesium Thixomolding enables manufacturers to integrate the mechanical and thermal conductivity properties of magnesium into their products.

Thriving Design

Facebook page: Facebook

Services:

- Manufacturing small parts

- Efficient and clean manufacturing process

- In-house production of products

- Focus on quality and reliability

- Extra capacity to accommodate customer orders

This injection molding company based in Fort Collins, CO specializes in manufacturing small parts with a focus on quality and reliability. They have the capability to produce their own products in-house and also offer extra capacity for manufacturing client-specific items.

For inquiries about their efficient and clean manufacturing services, they can be contacted at 970.670.0793 or via email.

Colorado Molded Products Co

Company: rubbermolding.org

Services:

- Custom rubber moldings

- Bonded rubber

- Compression molding

- Grommet edging

- Manufacturing using high caliber workmanship

Colorado Molded Products Company is a leading manufacturer of custom rubber moldings and bonded rubber. With nearly 75 years of experience in the industry, they are known for their high-quality products, made with precision and workmanship.

Based in Englewood, CO, this American company guarantees defect-free parts and is respected as one of the most diversified molded rubber product manufacturers in the country.

Relucent Plastics

Company: relucentplastics.com

Services:

- Insert molding

- Clean room molding

- Processing of advanced materials

- In-house tooling

- Customized assembly solutions

Relucent Plastics Solutions is a leading injection molding company specializing in advanced technologies for insert molding, clean room molding, and processing of advanced materials. With their in-house tooling expertise and customized assembly solutions, they provide strategic partnerships that drive success in the industry.

Optimim

Contact phone: (207) 842-4880

Facebook page: Facebook

Services:

- Manufacturing complex, small metal components

- High quality, complex, precision metal components less than 160 grams

- Metal injection molding (MIM) process

- Creation of geometrically complex, dense parts

- Integration and consolidation of multiple components into a single molded piece

OptiMIM is an injection molding company specializing in the production of high quality, complex, precision metal components weighing less than 160 grams. Combining plastic injection molding and powdered metallurgy, their engineers employ the metal injection molding (MIM) process to create dense, geometrically intricate parts that cannot be achieved through conventional powder metal techniques.

The MIM process allows for the integration and consolidation of multiple components into a single molded piece, eliminating the need for separate casting and assembly processes.

Recap