Discover the step-by-step process to efficiently and safely wire a metal building for optimal functionality.

Wiring a metal building involves a series of steps that ensure safety and functionality. From planning the layout to installing the electrical boxes and running wires, each step plays a pivotal role in a successful installation.

This article will guide you through the process, providing a comprehensive overview of each stage. It will detail the necessary materials, safety precautions, and best practices, ensuring you have all the information you need to wire your metal building effectively and efficiently.

So, whether you’re a seasoned professional or a DIY enthusiast, this guide will serve as a valuable resource.

Key takeaways:

- Familiarize yourself with metal building wiring codes

- Plan your steel building electrical conduit runs carefully

- Use the right tools for wiring a metal building

- Secure stranded wiring properly to prevent future issues

- Adhere to safety precautions and local electrical codes when wiring a metal building.

Understanding Metal Building Wiring Codes

Familiarizing yourself with metal building wiring codes is an essential first step. These codes, which vary by location, are designed primarily to ensure safety. They outline the specifications for wiring materials, installation procedures, and system inspections.

1. Local Building Codes: Regulations differ from one jurisdiction to another. Check with local authorities to understand the specific wiring guidelines for your area.

2. National Electrical Code (NEC): This is a widely-accepted standard across the U.S for safe electrical installation. It’s frequently updated, so always consult the latest version.

3. Wiring materials: Understand the approved types of cables, switches, and outlets. Wire gauge size, type of metal used, and insulation are among the factors to consider.

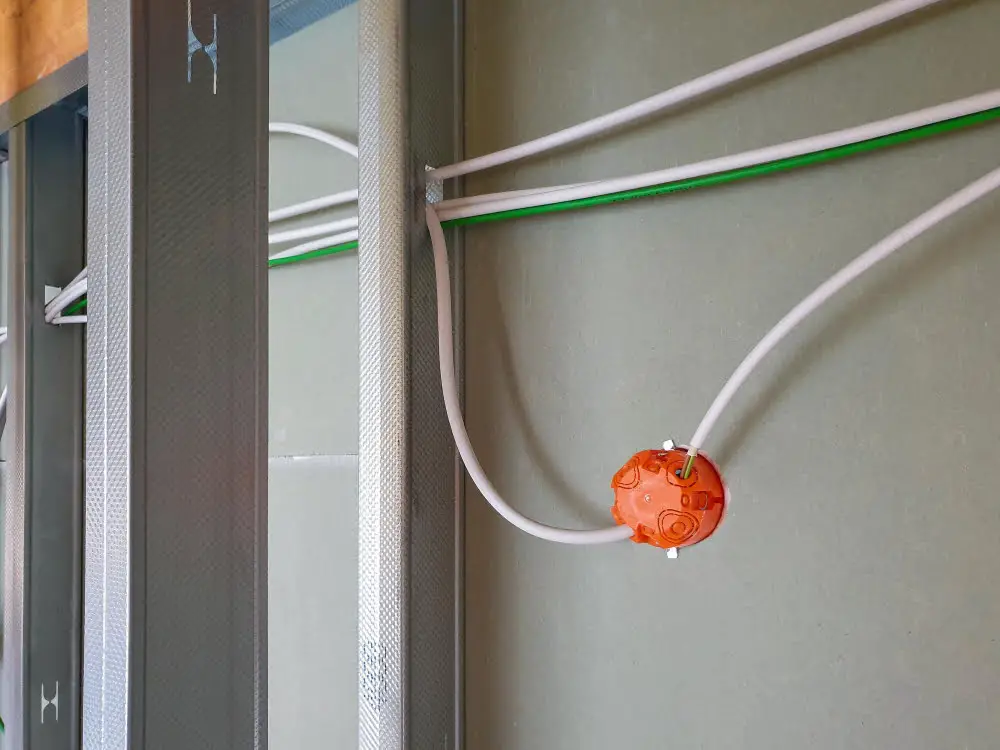

4. Conduit Requirements: Metal buildings often require conduit – a tube used to protect and route electrical wiring – for added protection against the possibility of electrical fires.

5. Inspection Standards: Finally, know the inspection standards for your wired system. Not only does this ensure compliance with the law, but it also ensures the safety of the building’s occupants. Regular testing and inspections are mandatory and are often performed by licensed professionals.

Planning Our Steel Building Electrical Conduit Runs

Before work commences, a blueprint of the building layout is essential. This indicates key areas where power outlets and lighting fixtures should be located. Tailor this map to your needs, factoring in machinery, workspaces or areas requiring special consideration.

Next, calculate the total electrical load. Each device’s wattage and their frequency of use matter. Oversights can mean strain on the system or frequent tripping.

For conduit routes, plan to run them along walls and ceiling beams. It minimizes accessibility issues later and enhances the building’s aesthetics by keeping wires hidden.

Finally, decide the best type of conduit to use. Metallic conduit, such as EMT (Electrical Metallic Tubing), is often favored due to its durability and formidable protection against factors like shock and fire hazards. Various sizes are available: the larger the conduit, the more wires it can carry. Using oversized conduit can give flexibility for future expansion.

Remember, local building code adherence is a non-negotiable. Codes vary, but they are created to ensure safe, efficient electrical systems. Always consult or hire a professional electrician if you have doubts.

Basic Tools Needed for Wiring a Metal Building

To ensure a smooth wiring process, the right set of tools is crucial. Firstly, a wire stripper is essential for removing the plastic insulation from the electric wires without damaging the inner metal.

An electrical tape comes in handy for insulating wire splices and preventing electric currents from becoming a potential safety hazard.

Next is a fish tape, making it possible to route new wiring through walls and electrical conduit.

Non-contact voltage testers can prove quite useful to detect if a wire is live before you touch it, adding a layer of safety.

Finally, a screwdriver set and a cordless drill will often be required for attaching metal boxes, driving in screws, and drilling holes. Equipped with these tools, the process can be more efficient and less hazardous.

Securing Stranded Wiring

When handling stranded wiring, it’s essential to firmly secure each strand to prevent it from coming loose over time. Stranded wires are highly flexible and great for routing around obstacles; however, this flexibility requires a bit of additional attention during installation.

1. Use Wire Connectors: Tools such as wire nuts are designed to twist strands together and hold them securely in place.

2. Apply Heat Shrink Tubing: This technique situates a piece of heat shrink tubing over the wire connection, creating a solid joint when heat is applied.

3. Practice Crimping: With appropriate connectors, crimping forms a strong physical connection by compressing the stranded wire within the connector using a crimp tool.

4. Opt for Soldering: Although more complex and requiring specialist equipment, soldering strengthens the joint by melting a filler metal into the connection.

Remember, always ensure each wire is snugly fit into its terminal using a firm tension that neither under-tightens nor over-tightens. The guiding principle is to have connections that are certain to endure the test of time.

The Real Work

Once the required tools are at hand and preparations are complete, it’s time to step into the central part of the project: actual wiring. This process encompasses numerous stages, each requiring a methodical approach.

1. Circuit Planning: Decide on the number of circuits needed and their respective locations. Make sure to consider both current and future power requirements.

2. Wire Installation: Route the wires through the conduit you’ve already secured. Each wire color indicates a different purpose, be sure to connect them correctly: black (hot), white (neutral), green or bare (ground).

3. Device Connections: Connect outlets, switches, and fixtures to the appropriate wires. Ensure proper grounding for safety.

4. Breaker Box Installation: This serves as the control center for all the electricity in the building. Each circuit connects to an individual breaker within the box. Proper installation is crucial to prevent electrical hazards.

5. Adhering to Code: Always ensure adherence to the local electrical code for every step you take. These codes exist to maintain safety standards.

Remember, working with electricity demands utmost precaution. If, at any point, you feel unsure, don’t hesitate to consult a professional electrician.

Handling Electrical Safety in Metal Building Wiring

Utilizing proper safety measures is paramount when dealing with any electrical wiring project. Here are some key safety aspects to keep in mind when wiring a steel building:

- Turn Off Power: Before any work begins, ensure that the power is shutdown at the main circuit box to avoid accidental electrocution.

- Use Insulated Tools: This helps decrease the risk of electrical shock.

- Grounding: Always ground all electrical components. This is crucial for controlling potential electrical faults because it allows the current to safely flow directly into the earth.

- Wear Protective Equipment: Rubber-soled shoes and insulated gloves can provide an extra layer of protection against accidental electric shock.

- Professional Inspection: Once the wiring is complete, have a professional electrician check the work to ensure everything is safe and up to code.

Remember: safety must never be compromised. Comprehensive precautions and adherence to electrical codes are critical in wiring a metal building.

Testing the Steel Building Electrical Conduit Runs

Before connecting your metal building’s wiring to the main power supply, it’s essential to conduct testing. The key goal here is to ensure the safety and efficacy of your work.

1. Checking the Continuity: Cross-check your electrical circuit’s continuity using a multimeter. Find any breaks or shorts in the wirings to ensure all connections are working effectively.

2. Testing the Polarity: Incorrect polarity can be disastrous and can cause shocks or potential fire hazards. A lens voltmeter is useful here to identify if the live, earth, and neutral wires are correctly wired.

3. Verifying Wire Sizes: Wires in conduits may overheat if not aptly dimensioned for the load they’ll be bearing. Each section of the wire should match the current it will carry.

4. Grounding Test: One rule that should never be compromised in metal building wiring is proper grounding. Verify the grounding of each outlet using a ground tester.

After you’re confident your metal building’s electrical conduits pass these tests, you can proceed to connect it to the power supply.

FAQ

Does wiring in a metal building need to be in conduit?

Yes, wiring in a metal building needs to be in conduit for protection against wear, considering the fact that metal naturally conducts electricity.

Can you wire a metal building with Romex?

Yes, you can wire a metal building with Romex; however, it is essential to protect the cable from potential damage.

How do you bond a metal building?

To bond a metal building, install two rods at opposite corners, connect the steel frame to these ground rods using a solid #6 copper wire or larger, and ideally bond the rebar in the concrete to the building frame at all four corners.

What is the best conduit for garage wiring?

The best conduit for garage wiring is the electrical metal conduit due to its surface application adaptability and protection against rodents.

What safety precautions should be taken when wiring a metal building?

When wiring a metal building, it’s crucial to use the correct conduit materials, wear protective gear, ensure all wires are securely insulated, follow national and local electrical codes, and use a licensed electrician for installation to guarantee safety.

Are there specific codes or regulations that need to be considered while wiring a metal building?

Yes, there are specific electrical codes, like the National Electric Code (NEC), that must be followed while wiring a metal building to ensure safety and efficiency.

What are some common mistakes to avoid during the wiring process in metal buildings?

Common mistakes to avoid during the wiring process in metal buildings include failing to properly ground electrical systems, using incorrect wire type or gauge, neglecting electrical codes, and not planning for future electrical needs.

Recap