Discover how to insulate your corrugated metal building because effective insulation can dramatically increase energy efficiency, reduce noise, and provide long-lasting benefits.

Insulating a corrugated metal building can significantly enhance its energy efficiency, comfort, and overall performance. The process primarily involves selecting the right insulation material, preparing the building interior, and installing the insulation correctly.

This article will guide you through each step, from choosing between popular insulation types like fiberglass, spray foam, and rigid board, to the actual installation process.

Detailed information on potential challenges and expert tips for overcoming them are also included, making this a comprehensive resource for your insulation project.

Key takeaways:

- Insulating corrugated metal buildings improves energy efficiency and comfort.

- Popular insulation options include foil bubble, spray foam, and batts and rolls.

- Proper installation involves careful measurement, secure application, and sealing.

- Understanding U-values and R-values helps in selecting the right insulation.

- Vapor retarders, maintenance, and addressing condensation are important considerations.

Understanding the Importance of Insulation in Metal Buildings

Insulation plays a key role in metal buildings, essentially acting as a thermal barrier. It effectively regulates the temperature inside the structure, ensuring a comfortable environment irrespective of the exterior weather conditions.

Besides its temperature control function, insulation also reduces energy consumption and thereby, operational costs of the structure. By minimizing heat transfer through the building envelope, it lessens the demand on heating and cooling systems.

On another note, insulation also aids in noise reduction, providing a quieter internal space. It’s noteworthy that well-insulated buildings contribute to sustainable living by reducing the structure’s carbon footprint.

Therefore, insulating your metal building rightly is a critical component, not just for comfort and cost savings, but also for achieving environmental sustainability.

Types of Insulation Suitable for Metal Buildings

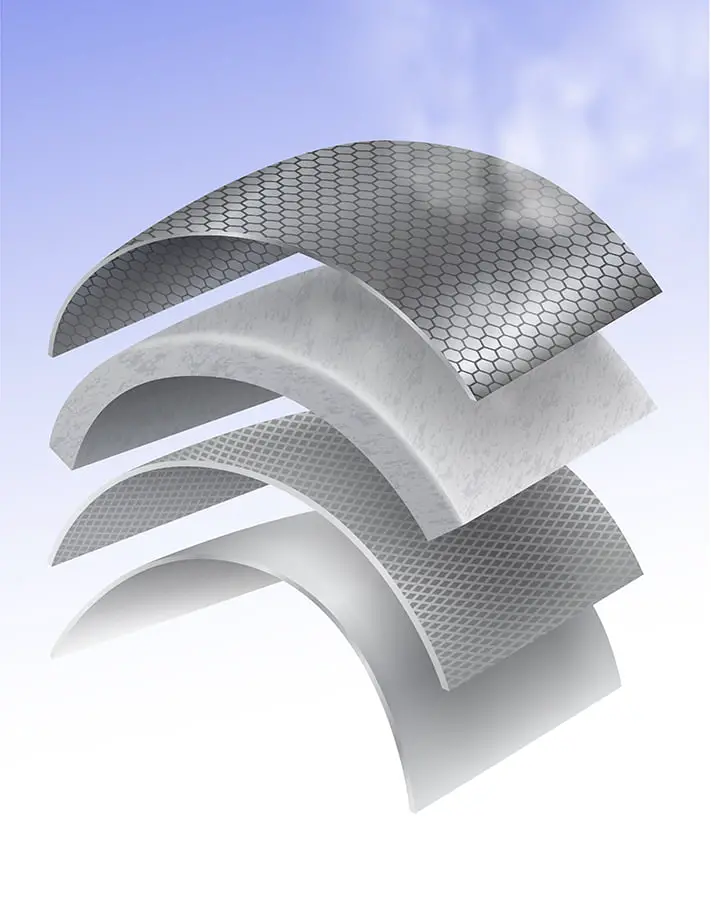

Several types of insulation work well with metal buildings, each offering unique advantages and characteristics, suitable for various conditions and specific needs.

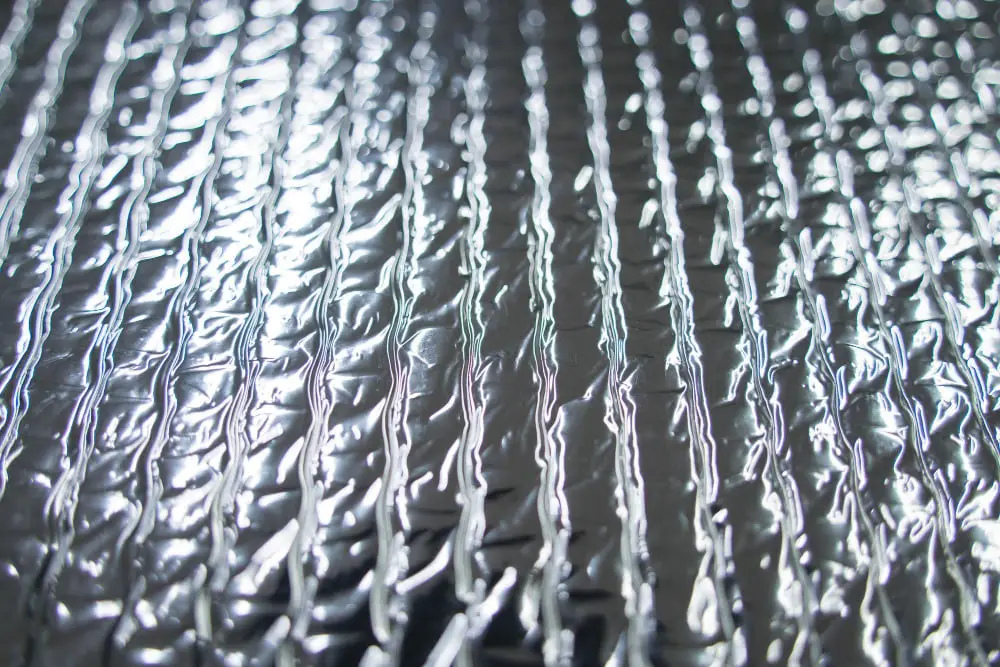

Foil bubble insulation is a popular choice due to its high reflective surface. It provides exceptional heat retention and is perfect for controlling temperatures in extreme weather regions.

Spray foam insulation offers a comprehensive solution as it fills, seals, and insulates in one step. It is highly effective in reducing heating and cooling costs, thus promoting energy efficiency.

Another category is batts and rolls insulation, comprised primarily of fiberglass or mineral wool that is flexible and relatively easy to install. It’s superb for soundproofing while offering excellent thermal resistance.

Rigid board insulation made of polystyrene, polyurethane, or fiberglass provides excellent heat resistance and structural strength, making it ideal for roofs and exterior walls.

Lastly, consider reflective insulation, commonly made up of foil-backed paper or plastic bubble forms. It is excellent in preventing excessive heat gain, providing a sustainable cooling effect in warmer climates.

Choosing the right type largely depends on your building’s location, design, and the specific thermal and acoustic requirements of the space.

How to Install Foil Bubble Insulation in a Metal Building

To begin, take careful measurements of the wall and roof dimensions of the building. Make sure to purchase enough foil bubble insulation material, accounting for slight overage.

Next, place the insulation on the inside of the building, running vertically from the base to the top of the walls, then horizontally across the roof. Secure the insulation to the metal structure using double-sided industrial strength tape. This tape should be strong enough to hold the weight of the insulation material.

Once the insulation is trimmed and in place, you will need to properly seal off the insulation. Use a high-quality metal tape to seal the joints, ensuring a tight barrier against all air. Remember, the goal is to retain the internal temperature of the building and shield it from external elements. Therefore, no gaps should be present at any point in the insulation.

Finally, add furring strips over the insulation. It provides a secondary anchor point and creates an air gap between the insulation and the final layer of interior wall. This gap aids in the thermal resistance properties of the insulation, reducing potential for heat transfer.

Important to note that if your metal building will be exposed to high moisture, considering a vapor retarder layer can be beneficial to prevent condensation buildup. This step, however, is highly dependent on your existing environmental conditions so assess accordingly.

In essence, installing foil bubble insulation in a metal building involves careful measurement, secure application, thorough sealing, and consideration for moisture levels. By following these steps, you’re well on your way to a well-insulated structure.

The Process of Installing Spray Foam Insulation

Prior to the application, ensure the surface is clean and free from dust or oil. For optimal results, the temperature of the spray foam components, surface to be insulated, and the environment should be maintained between 60°F to 80°F.

Start by setting up your spray foam kit according to the manufacturer’s instructions. Typically, this includes connecting the hoses, opening the valves on the cylinders, and adjusting the output pressure. Make sure to use appropriate protective equipment, such as gloves and safety goggles.

Spray foam can be applied using the ‘picture framing’ technique. Begin by spraying around the perimeter of the area to be insulated, then fill the center in a consistent, even fashion. Maintain a uniform thickness throughout application.

After spraying, the foam will begin to expand immediately, filling nooks and crannies to form a seal. Allow adequate time for the foam to cure; it will become rigid and can be trimmed, painted or covered with a protective layer if required.

This spray-foam method leads to a comprehensive thermal barrier, reducing energy costs, and providing resistance to moisture, air and noise intrusions. Remember that professional installers are trained in handling the materials and providing a thorough insulation that meets building codes. You might want to consider hiring one to ensure a complete and proper installation.

Steps to Install Batts and Roll Insulation

Start with a premeasured diagram of the area you aim to insulate. After proper measurements, choose the appropriate sized batts or rolls adequate for your metal structure. To start the installation, the insulation should lay perpendicular to the metal building purlins, or struts, that support the building structure.

Following are the steps you need to take:

- First, unroll the insulation on the surface and cut it according to the measured length. It’s essential to use a sharp utility knife for clean, precise cuts.

- Second, secure one edge of the insulation to a purlin. Adhesive, staples, or unique fasteners designed for metal structures can be used for this purpose.

- Third, after securing one edge, extend the insulation across to the opposite purlin. Make sure to pull it tight, preventing any sagging or gaps where heat can escape.

- Fourth, secure the opposite edge of the insulation to the purlin, ensuring it’s firmly in place.

- Fifth, repeat the process for the other sections, providing care to overlap the edges of adjoining insulation runs. This overlap ensures a solid barrier, reducing the chances of heat loss.

Always remember, safety should be paramount during the installation process. Make sure to use gloves, eye protection, and long sleeves to protect your skin from the glass fibers present in many insulating materials.

Explaining U-Values and R-Values in Insulation

Crucial to understanding insulation is grasping the definitions of U-Values and R-Values.

The R-Value measures the capability of the insulating material to resist heat flow. Higher R-Values equate to better insulation performance. In contrast, the U-Value is an indicator of how much heat is lost through the insulation. Lower U-Values signify superior thermal performance.

Determining both values is essential in selecting the right insulation for your metal building. Given the diverse climate conditions, knowing the local recommended R-Values is crucial. Exceptionally cold areas require higher R-Values to ensure sufficient heat retention inside the building.

Choice of insulation material is key as well. Materials with a higher R-Value per inch, like spray foam or rigid board, offer optimal resistance to heat flow, hence presenting a good choice for areas with confined spacing. On the other hand, the choice for large insulating spaces often leans towards materials with lower per inch R-Values, like fiberglass or cellulose.

Remember that effectively insulating your building significantly relies on correct installation combined with the appropriate R-Values and U-Values for your specific needs. Thus, understanding these terms is fundamental in achieving optimal thermal performance for your metal building.

Understanding Vapor Retarders in Insulation

Vapor retarders play a vital role in preserving the integrity and efficiency of insulation by impeding the movement of moisture. In metal buildings, they contribute to preventing corrosion and mold growth, thus contributing to the building’s overall durability.

1. Significance of Placement: Placed on the warm side of the insulation, the vapor retarder prevents moisture from penetrating into the insulation material.

2. Material Choices: These are available in multiple materials such as plastic, aluminium foil, and special paints. Your choice depends on local building codes, climate, and budget.

3. Use in Mixed Climates: In climates with both hot and cold seasons, the positioning should be based on the dominant temperature. The rule of thumb is, it should be towards the side from where most of the humidity comes.

4. Functionality in High Humidity: In places with high humidity, vapor retarders are crucial in maintaining insulation performance and prolonging the life of the metal structure.

Understanding the correct use of vapor retarders in relation to climate and insulation type ensures an efficient insulation system for a corrugated metal building.

Preventing Mold, Mildew, Rust, and Corrosion During Insulation

One surefire way to avoid moisture-related damage during and after insulation is by using good quality vapor retarders. They are placed between the insulation and the outer facing, stopping humidity from permeating and condensing on the metal. For metal buildings without inner linings, vinyl-reinforced fiberglass insulation is advisable as it is already fitted with a vapor retarder.

Strategically placed vents can clear out moisture from insulated areas, challenging mold and mildew’s survival. Ensure the vents are designed to allow continuous airflow while also preventing ingress of rainwater.

Use rust-resistant coating to protect metal surfaces from corrosion. Electrochemical rust-proofing is highly recommended as it gives the metal self-healing abilities, allowing it to recover from minor scratches and abrasions. Regular inspection and maintenance of these coatings help keep rust at bay.

For the prevention of mold and mildew, establish a regular cleaning regimen. Use mildew-resistant paints and, if possible, insulation materials treated with an antimicrobial agent.

Remember, meticulous planning, quality materials and periodic inspections are the key elements to safeguard your metal building from mold, mildew, rust, and corrosion.

Dealing With Condensation During Metal Building Insulation

To efficiently deal with condensation, it’s crucial to understand its origins. Condensation, the change of water from its gaseous form to liquid, typically emerges when humid air contacts a cold surface, often the metal walls or roof of a building.

Firstly, a vapor retarder may be an effective barrier against moisture penetration, significantly reducing the risk of condensation inside the metal building. This is typically installed on the warm side of the insulation, in consideration of the local climate.

Secondly, consider the effect of thermal breaks. They significantly decrease temperature transfer from the metal building’s exterior to the interior, reducing the risk of condensation on the interior surfaces.

Ventilation also plays a vital role in moisture management. Well-designed ventilation prevents the buildup of hot, damp air, combating condensation effectively.

Finally, insulation itself, properly installed, acts against condensation, as it keeps the interior metal walls and roof above the dew point—the temperature at which water vapor condenses.

Clearly, addressing condensation is a multidimensional task involving thoughtful selection of insulation, correct application of vapor retarders, smart design for ventilation solutions and understanding of thermal breaks.

Avoiding Common Mistakes During Metal Building Insulation

Firstly, it’s essential to ensure that the insulation is properly secured. Using staples all around the building envelope helps maintain the integrity of the insulation material.

Next, avoid gaps where the insulation overlaps by adequately overlapping and sealing joins. This action helps maintain uniform temperature and prevents air leakage.

Ensure compliance with local and state building codes. Ignoring these guidelines can result in legal ramifications and structurally unsound insulation.

Finally, mindful planning to correctly identify the type and quantity of insulation required before beginning the project minimizes cut-offs and waste. Not properly assessing waste can lead to cost overruns and unnecessary environmental impact.

By keeping these points in mind, insulation-related errors can be significantly reduced, leading to a more efficient metal building.

Maintaining Metal Building Insulation for Longevity

Insulation maintenance is crucial for the longevity of your metal building. Regular inspections, at least twice a year, should form part of your building maintenance routine. Look for signs of wear and tear, mold, dampness, or damage from pests.

Patch minor rips or tears with a quality tape to preserve the thermal barrier, but replace severely damaged sections to avoid thermal bridges. Remove any mold growth promptly, as it can degrade the insulation material over time. In extreme cases, consider using a mold-resistant insulation product.

Lastly, ensure that your building has adequate ventilation, especially in high condensation areas like bathrooms or kitchens. Correct ventilation will prevent moisture build-up, reducing possible water damage and mold growth, thereby enhancing the longevity of your metal structure.

Moreover, consult with a professional if you’re unsure about maintenance procedures or dealing with insulation issues. A well-maintained insulation system will lead to an energy-efficient, comfortable, and durable metal building.

FAQ

How do you insulate corrugated metal walls?

To insulate corrugated metal walls, you can employ either foil bubble insulation, spray foam insulation, or batt and roll insulation, all of which should be installed between furring strips attached to the building’s studs.

How do you insulate a sheet metal building?

To insulate a sheet metal building, one of the simplest and most effective methods is to use spray foam insulation, especially when the metal panels are already attached to the frame.

What is the best insulation for sheet metal building?

The best insulation for a sheet metal building is fiberglass insulation.

How do you insulate a metal building that is already built?

Insulating an already built metal building typically involves the application of a banding system involving steel bands screwed to the underside of the metal purlin, creating a grid system on the roof.

What are the most effective insulation materials for steel-framed buildings?

The most effective insulation materials for steel-framed buildings include spray foam, fiberglass, and rigid board insulation.

How does the installation process for metal building insulation differ from traditional insulation methods?

The installation process for metal building insulation typically involves fastening the insulation to the interior of the metal building using adhesive or mechanical means, a practice that differs from traditional insulation methods, which usually involve placing the insulation between wall studs in a residential setting.

Can insulation upgrades improve energy efficiency in existing metal buildings?

Yes, insulation upgrades can significantly improve energy efficiency in existing metal buildings.

Recap