Double bubble insulation is essential for your metal building project because it can significantly increase energy efficiency, ease of installation, and overall moisture control.

Double bubble insulation is an effective solution for controlling temperatures in metal buildings.

This guide will provide you with a straightforward, step-by-step process to install double bubble insulation in your metal structure.

From preparing the surface to the final tape-down, every critical detail will be covered.

Whether you’re a seasoned builder or a DIY enthusiast, this guide will equip you with the knowledge to efficiently and effectively insulate your metal building.

As you follow along, you’ll find practical tips and insights to ensure a smooth installation process.

Get ready to optimize your metal building for energy efficiency and comfort.

Key takeaways:

- Double bubble insulation increases energy efficiency and moisture control.

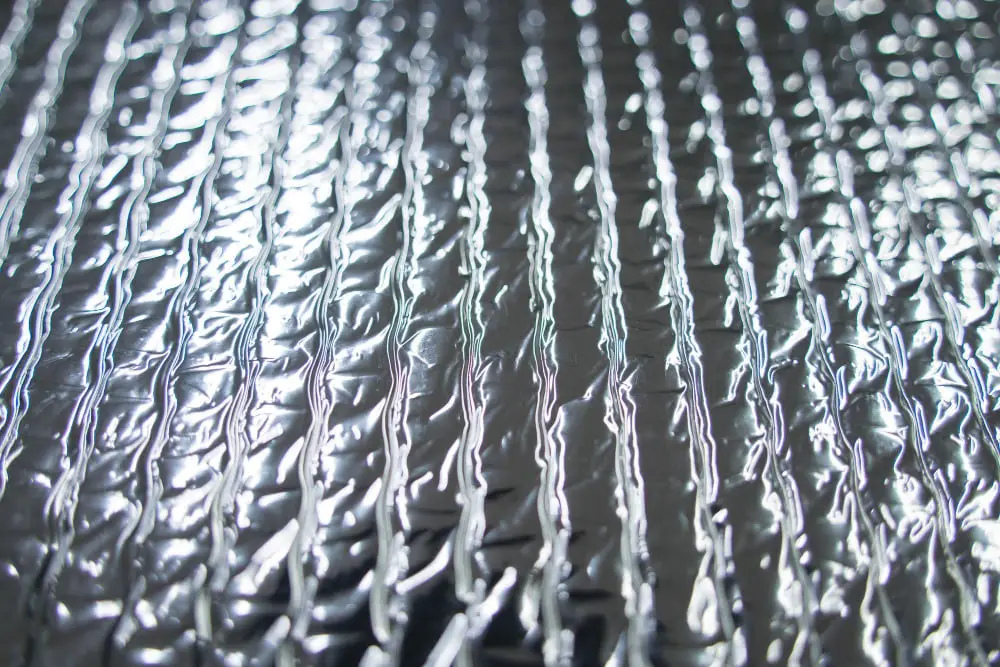

- Double bubble insulation consists of two layers of air bubbles sandwiched between metalized film.

- Proper measurement, seam seals, and firm installation are essential for installation.

- Common problems include gaps between insulation sheets and sagging.

- Regular maintenance and inspection ensure the longevity of double bubble insulation.

Understanding What Is Double Bubble Insulation

Double bubble insulation, as the name implies, involves two layers of air bubbles sandwiched between layers of reflective metalized film. This design promotes superior insulating abilities and is especially revered for its resistance to heat transfer and outside elements.

Designed particularly for structures with minimum to no existing insulation, this type of insulation serves as an efficient thermal block. In warmer climates, it shields the interior from exterior heat, and in colder climates, it keeps the warm air inside, reducing heating costs.

Ideal for use in metal buildings, double bubble insulation also inhibits condensation, a vital consideration due to the metal’s propensity for condensation build-up, which can subsequently lead to rust and corrosion.

Due to its thin, lightweight structure, double bubble insulation is easy to handle and install, making it a popular choice for DIYers and professionals alike. It is also highly durable and known for its longevity, making it a cost-effective choice in the long run.

The reflective surface of the metalized film also has the added advantage of providing substantial light reflection within the structure, enhancing interior visibility and possibly reducing lighting costs.

Remember, while double bubble insulation can enhance energy efficiency and comfort in your metal building, professional installation is always recommended to ensure the maximum benefit and longevity of the product.

Essential Tools and Materials for Installing Double Bubble Insulation

Before embarking on the installation process, having the right tools and materials at your disposal is crucial. This will make the process not only smoother but also more efficient. Here’s what you’ll need:

- Double Bubble Insulation: Known for its reflective efficiency, it provides an excellent barrier against radiant heat transfer. It significantly improves the energy efficiency of metal buildings.

- Utility Knife: Used for cutting insulation to required size. A sharp, reliable utility knife ensures accurate and clean cuts.

- Tape Measure: To measure the length and breadth of the wall. Accurate measurements are vital to avoid wastage and ensure fit.

- Safety Glasses: Protective eyewear is essential to safeguard against potential accidents during handling or cutting the insulation.

- Work Gloves: They help prevent cuts and scrapes while dealing with metal edges.

- Staple Gun: To fasten the insulation to the metal building’s frame. A durable, easy-to-handle staple gun will ease the job.

- Reflective Aluminum Foil Tape: For sealing the joints and seams after the insulation is installed. This tape creates a continuous thermal barrier that enhances the effectiveness of the insulation.

- Straight Edge: Helps keep your cuts of the insulation neat and precise.

These tools and materials are instrumental in ensuring a successful installation of double bubble insulation in a metal building. Before beginning, ensure all these items are within easy reach and that safety precautions are taken.

Step-by-Step Instructions On How to Install Double Bubble Insulation in Metal Buildings

Begin the installation process by accurately measuring your building’s walls, ceilings, and floors. Acquire a roll of double bubble insulation that meets these dimensions, bearing in mind a little extra would be necessary to ensure full coverage.

Firstly, start with the installation on the walls. Position the insulation against the wall, ensuring to maintain a flush connection with the furring strips – the vertical slices on the metal panels. You can secure the insulation in place using a staple gun, attaching it to the furring strips.

Next, shift your attention to the roof. The process is similar to wall insulation. Roll the double bubble layer across the roof panels, attaching it directly to the furring strips too. It’s recommended to start from the edge and work your way towards the center for a more streamlined outcome.

The third step is to install the insulation on the floor or base of the building. Here, you’d lay the double bubble sheet on the ground before your final flooring is set.

Remember to consider the seams between the insulation rolls. Seal these with foil insulation tape, providing a consistent, uninterrupted barrier. This enhances the overall insulation effectiveness by reducing thermal bridging – an area where heat flow is high.

Finally, ensure all the areas are properly covered, any exposed regions could derail the insulation’s performance. The aim is to make your metal building more energy efficient, providing a comfortable internal atmosphere regardless of external weather conditions.

Best Practices for Installing Double Bubble Insulation in Metal Buildings

To ensure optimum performance of double bubble insulation, following specific recommended guidelines is paramount.

1. Proper Measurement: Measure the area of installation accurately. This helps in cutting the insulation precisely, minimizing wastage and maximizing effectiveness.

2. Seam Seals: Make use of a high-quality seam tape. This ensures that the joints between individual insulation pieces are sealed well, preventing air leakage and enhancing insulation performance.

3. Firm Installation: Attach the insulation firmly to the building structure using suitable fasteners to prevent drooping or loosening over time.

4. Radiant Barrier Direction: Make sure the radiant barrier side of the insulation faces the inside of the building. Misplacing the radiant barrier can reduce insulation effectiveness.

5. Avoid Punctures: Be cautious during installation to avoid unintentionally puncturing the insulation. Holes or tears can compromise the insulation capability.

6. Condensation Management: Don’t forget to include a vapor barrier if your region has high humidity levels. This helps manage condensation, protecting both the insulation and the metal building.

Always abide by these guidelines to guarantee the double bubble insulation performs at its highest potential.

Troubleshooting Common Problems in Double Bubble Insulation Installation

While the installation process is straightforward, certain problems may arise.

First, gaps between double bubble insulation sheets can impact its performance. Limit this issue by applying a unique tape specifically used for this kind of insulation, ensuring a tight and securer overlap between the sheets.

Insulation sagging is another common problem. To address this, fasten the double bubble insulation appropriately to the building panels using furring strips or adhesive. Remember, it’s crucial the material conforms to the contour of the metal building to maintain insulation integrity.

Dents and punctures can harm insulation efficiency. Treat them immediately with patching tape, preventing environmental factors from infiltrating the insulation.

Lastly, improper cutting can result in material wastage. Measure the exact length required and cut precise lines. A common trick is to use a straight edge and sharp knife to achieve neat and accurate cuts.

Understanding these challenges can save time, efforts, and secure maximum insulation benefits.

Maintenance and Longevity of Double Bubble Insulation in Metal Buildings

To ensure the effectiveness and longevity of double bubble insulation, regular inspection is paramount. Look for signs of damage such as tears, punctures, or sagging. It’s recommendable to resolve these issues promptly to retain the insulation’s thermal efficiency.

Next, moisture can be a major enemy of insulation. Avoid any contact with direct water, be it from leaks or condensation. This requires careful check-ups especially during rainy seasons.

On some occasions, dust and grime may accumulate on the surface. Although this won’t necessarily impair the insulation’s functioning, it might lead to reduced reflectivity and hence, a mild decrease in efficiency. In such cases, gently clean the surface with a damp cloth.

Lastly, although rare, pests can sometimes nest in insulation material. Be on the lookout for any signs of infestation. If you spot one, consult a pest control expert without delay.

With the right maintenance approach, double bubble insulation can prove not only to be functional today but also remain operationally efficient for years to come.

Benefits of Using Double Bubble Insulation in Metal Buildings

Affordability and efficiency are two of the key benefits driving the popularity of double bubble insulation in metal buildings. This material delivers a high return on investment by providing effective insulation at a surprisingly low cost.

Double bubble insulation aids in climate control, effectively reducing the costs associated with heating and cooling a building. Whether it’s scorching summer heat or freezing winter temperatures, this material works diligently to maintain stable indoor conditions.

The reflective nature of double bubble insulation helps in blocking radiant heat, preventing hot or cold air from permeating the building’s interior. This keeps your building comfortable, regardless of extreme outdoor weather conditions.

Its lightweight nature makes double bubble insulation easy to install without requiring heavy machinery or extensive labor. This not only reduces initial installation costs but also makes future insulation upgrades or replacements straightforward.

Lastly, the robust structure of double bubble insulation enhances the overall durability of the building structure. It resists typical environmental threats such as condensation, pests, and mould, thereby extending the lifespan of the metal structure.

By counting on double bubble insulation, the owners of metal buildings can reap multiple rewards, paving the way for long-term sustainability and cost-effectiveness.

FAQ

How do you fasten insulation in a metal building?

Insulation in a metal building is secured by adhering it to the I-beams using double-sided tape for immediate hold and super metal sealant for durable grip.

Which side of bubble insulation faces out?

The side of bubble insulation that faces out should be the reflective part during hot weather; while in freezing conditions, the reflective part should face inside.

Which way does bubble insulation go?

Bubble insulation should be spread over the metal joists or purloins with the shiny side facing up, ensuring a minimum air space of 1 inch (2.5 cm) between the insulating surface and the foil.

What are the essential tools for installing double bubble insulation in a metal building?

To install double bubble insulation in a metal building, you require essential tools such as a utility knife, construction grade tape, a tape measure, and a staple gun.

How does the placement of bubble insulation affect the thermal performance of a metal building?

The placement of bubble insulation directly impacts the thermal performance of a metal building, with optimal results being achieved when it is installed in the wall and roof cavities to reduce thermal bridging and enhance energy efficiency.

Are there specific safety measures to be followed while installing double bubble insulation in a metal building?

Yes, during the installation of double bubble insulation in a metal building, safety measures such as the use of protective gear, careful handling of sharp materials, securing the insulation in place, and maintaining clean work space should be strictly followed.

Recap