Explore the step-by-step process of constructing a robust, durable home using metal building materials for an eco-friendly and cost-efficient solution.

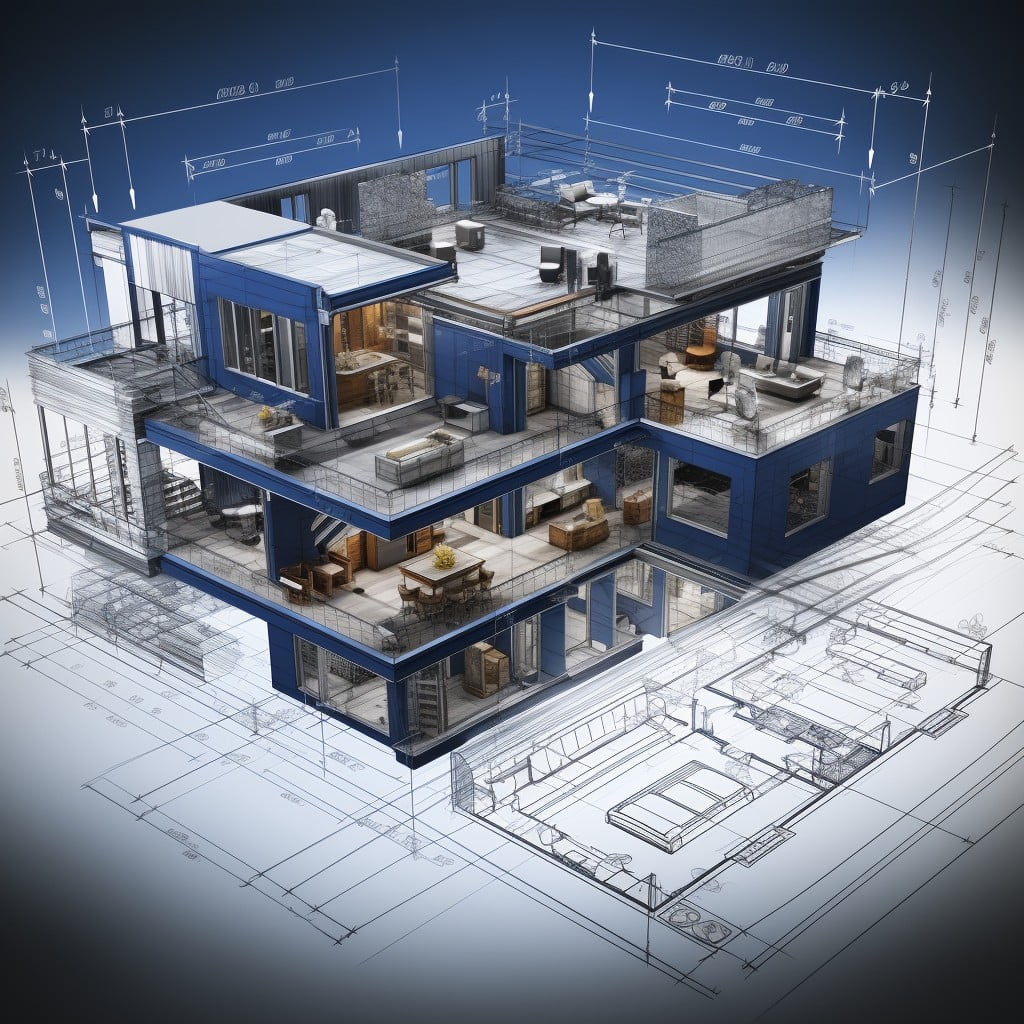

Building a house out of a metal building is an innovative, cost-effective, and sustainable approach to residential construction. This article will guide you through the process, from planning and design to the actual construction. We’ll discuss the benefits of metal buildings, what materials are needed, how to prepare the site, the steps to erect the building, and how to finish the interior. Our comprehensive guide will provide you with all the details you need to successfully build your own metal house.

So, whether you’re a seasoned builder or a DIY enthusiast, this article is your blueprint to constructing a durable, energy-efficient, and stylish metal building home.

Key takeaways:

- Metal buildings offer durability, speed, and long-term savings.

- Consider layout, windows, entrances, and local building codes.

- Prepare the site carefully, including water drainage and permits.

- Choose from concrete slabs, pier foundation, floating foundation, or screw piles.

- Follow a step-by-step process for erecting the metal building and prevent condensation with proper insulation.

Choosing Metal Building Homes: Pros and Cons

Indeed, metal building homes, or steel homes, offer a range of benefits that make them an attractive option for many homeowners. These structures are known for their durability, with steel being resistant to common issues that plague traditional wooden structures like termites, rot, and even fire, thus offering long-term savings on repairs and maintenance.

One key advantage with the construction of metal building homes is speed. Since these homes are pre-engineered in factories, on-site construction time is significantly reduced.

However, just like any other option, they also have certain drawbacks. The initial cost, for instance, might be higher than traditional homes due to the price of high-quality steel. It might not be as aesthetically pleasing to some given its industrial look and feel. Also, it conduces heat, therefore, necessitating the need for a robust insulation system, especially in areas with extreme weather.

Ultimately, the decision to choose steel homes boils down to the homeowner’s needs and priorities. Both the long-term financial benefits and occasional downsides must be taken into account for the most cost-effective, comfortable, and efficient outcome.

Creating Your Metal Building Home Blueprint: Key Considerations

Understanding the size and complexity of your desired home will aid in the crafting of an effective blueprint. First, decide on the number of rooms you’ll need, considering the purpose of each. Then, consider the layout; open-concept or divided spaces?

Don’t forget about window placements for natural light, and the locations of entrances and exits for security and ease of access.

Are you thinking of adding a second story or a basement? Such choices will affect the type of foundation you’ll need.

Remember, local building codes might dictate some aspects of your design, so always ensure your blueprint is compliant with all regulations.

Finally, consider using a professional designer for your blueprint. Their expertise can be invaluable, especially with the complex aspects of metal building homes.

Site Preparation: Making the Land Ready for Your Metal Building

Before embarking on the actual construction, preparing your site adequately is crucial for a smooth-running project. This process often begins with clearing the land which involves removal of trees, rocks and other debris. After this, grading or leveling is necessary to create a flat surface for your structure.

Remember, water drainage should be considered during this stage to prevent potential water-related problems. You can ensure this by slightly sloping the site.

Lastly, mark out the area where the building will be located, taking care to consider any future expansion plans. Employing the services of a surveyor can be beneficial in accurately mapping out your construction site, thus avoiding potential costly mistakes. Permit acquisition is also vital at this stage, so do ensure to comply with local building codes and regulations.

In a nutshell, the better your site preparation is, the smoother your construction process will be! Investigate, plan, and prepare well for optimal results.

Building Foundations: Options for Your Metal Building Home

Concrete slabs present as a prevalent option, providing durability and a solid base for metal homes. Attention to details, like ensuring even pouring and reinforcing with steel bars, can guarantee long-term stability. Employing this type correctly can prevent issues such as cracks or water seepage.

Alternatively, you might consider a pier foundation. Efficient for sloped sites, this variant makes use of cylindrical pillars constructed at key points across the building area. It supports the structure while minimizing soil disruption, making it a great eco-friendly choice.

For challenging terrains like marshy sites, a floating foundation, constructed using raft slabs, could be the answer. By evenly spreading the load, it mitigates the risks of ground instability and lends an extra layer of robustness.

Yet another viable alternative, screw piles, can be swiftly installed without needing a lot of earthworks. A good fit for locations with unstable soil or limited space, these helical anchors provide a quick and sturdy foundation.

Before making a choice, consult with an engineer or construction professional. Understand the pros and cons of each type, determine their compatibility with your building design, and factor in the environmental conditions of your construction site.

Erecting the Metal Building: Installation Process Explained

With all groundwork set, it’s time to erect the metal structure. This stage has different steps which are of utmost importance to maintain the building’s longevity.

1. Anchor Bolt Layout: Placement of anchor bolt is the first step. A proper layout ensures that columns align correctly.

2. Raising the Columns: Using cranes or mechanical lifts, columns are erected and fastened to anchor bolts.

3. Installing Girts and Purlins: Structural members called girts (horizontal) and purlins (vertical) are then attached to the columns. They add rigidity and provide a surface for attaching wall and roof panels.

4. Panel Installation: Metal panels are installed onto the girts and purlins. They serve as the walls and roofs and are available in various colors and finishes.

5. Adding Trim and Finishing Touches: Lastly, corner, eave, and ridge trims are attached, and necessary adjustments are made to ensure a tight fit and a polished look.

All steps must be followed to the letter, ensuring safety protocols are maintained. It’s crucial to keep in mind that precision in this phase greatly impacts overall building integrity.

Preventing Condensation: Solutions for Metal Building Homes

Determining the appropriate condensation control method can prove to be a pivotal decision in the overall lifespan of your metal building home.

To manage condensation, proper ventilation is necessary. This intervention creates air movement, dispelling moist air and preventing addition of moisture in the building.

An effective method also includes the use of vapor retarders. These barriers curb moisture migration, primarily by isolating the interior of the building from drastic temperature differences outside.

Installing dehumidifiers plays a significant role, as they erase excess moisture from the air, minimizing the potential for condensation.

Lastly, proper insulation, which we will address in the next section, forms the first layer of protection against condensation. It effectively hinders the contact between warm inside air and cool outer surfaces which typically leads to condensation. Remember, condensation is not just a passing issue, it’s a silent building killer. Proactively addressing it guarantees the longevity of your metal building home.

On we go to reveal some popular insulation types suitable for your metal building home.

Insulation for Metal Buildings: A Crucial Component

In ensuring comfort and energy efficiency, insulation serves as a quintessential element in metal building homes. When installed properly, it offers a barrier against weather extremes, creating a consistent interior environment regardless of outdoor conditions.

Two key performance indicators of insulation are ‘R-value‘ and ‘U-value‘. R-value measures the capability of an insulation material to resist heat flow, with a higher score translating to better performance. U-value, on the other hand, denotes the rate of heat loss; hence, a lower score is preferred.

The types of insulation vary based on material and method of application. Some popular choices include spray foam insulation, fiberglass batting, rigid foam board, and loose-fill insulation. Each type suits different needs regarding price, energy efficiency, and ease of installation. It pays to weigh out these factors carefully to make the best insulation choice.

Insulation thickness and installation methods are also critical. An inadequately insulated building might experience temperature fluctuations, leading to increased energy costs. So, remember to have professional advice on every step of this process to optimize your insulation fitting for a cozy, energy-efficient metal building home.

Comparing Insulation Types: Spray Foam, Fiberglass Batting, Rigid Board, and Loose Fill

With an array of insulation types available, each one has unique properties that cater to different needs. Let’s dig deeper into them.

Spray Foam, usually available in closed-cell and open-cell types, performs exceptionally well in sealing cracks and gaps. It minimizes air intrusion and provides an effective barrier against moisture. However, its installation requires professional assistance due to the complex process.

Next in line, Fiberglass Bats, a widely used insulation type, is cost-effective and easy to install. Nonetheless, it doesn’t seal as tightly as spray foam and often requires a vapor retarder to prevent moisture buildup.

Rigid Board insulation, typically made from foam or fibrous materials, offers high insulating values with less thickness. It’s ideal for flat roofs, basement walls, and cathedral ceilings. However, cutting and fitting these boards around obstacles can be challenging.

Lastly, Loose Fill or blown-in insulation, made of cellulose, fiberglass, or mineral wool, is excellent for adding insulation to existing finished areas and irregular spaces. However, it may settle over time and lose some effectiveness.

Understanding these fundamental differences can aid in choosing the right insulation for your metal building home.

Incorporating Electrical Systems in Metal Buildings: A Step-by-Step Guide

Wiring metal buildings requires a detailed, organized plan considering safety measures and building codes. The initial step is to draw a comprehensive wiring plan, including locations of outlets, switches, and light fixtures. This also involves identifying the types of circuits each area requires – normal, GFCI, or AFCI.

Next, installing metal outlet boxes which have been grounded to prevent electrical shocks becomes imperative. It’s recommended to use armored or metal-clad (MC) cable wiring to ensure protection against potential puncture threats from the metal structure.

Route your cables with the help of cable clamps while taking care to maintain ample space for insulation. Never forget: never run cables through the same holes as plumbing or gas lines.

After setup, double check all configurations before restoring the power. After validation, restore the power and perform tests to ensure all electrical systems function correctly.

Remember that while DIY projects can be fulfilling, electrical installations can pose serious risks if poorly handled. Engaging a licensed electrician often proves to be a wise decision, ensuring your metal building is safe and set up to code.

Adding Accessories to Metal Buildings: Gutters, Windows, Skylights, and Doors

When it comes to finishing touches on a metal building home, adding guttering is essential. It aids in proper rainfall water drainage, preventing rust and foundation issues that can occur over time. Depending on the setup, you can opt for common K-style or U-style half-round gutters.

Windows are another important feature for natural light and ventilation. You could choose single-hung, double-hung, sliding, or fixed windows based on your preferences and budget. If you want to maximize natural light, skylights could be an ideal inclusion. They ensure your home’s interior remains bright and airy.

Doors provide security and style to the structure. You can go for sliding doors, French doors, dutch doors, or overhead ones depending on the purpose of your space. For instance, overhead doors work exceptionally well for garages, while French doors considerably enhance aesthetics.

Remember, the design and position of these accessories can greatly influence the overall appeal and functionality of your home. Hence, planning these elements in advance and integrating them within the design is paramount. High-quality accessories not only add visual charm but also elevate the overall value of your property.

FAQ

Can I make a house out of a metal building?

Yes, it is entirely possible to construct a house from a metal building, leveraging its durability, low-maintenance, cost-effectiveness, customizable floor plans, and prolonged energy efficiency.

Can you put drywall in a metal building?

Yes, drywall can indeed be installed in a metal building.

Is it cheaper to Build a building out of wood or metal?

Overall, while the initial cost of building with wood may be lower, the long-term maintenance expenses make metal buildings a more cost-effective option.

How do you insulate a metal building?

To insulate a metal building, the use of fiberglass is recommended due to its cost-efficiency in terms of R-value and its ability to result in a durable and attractive finish when combined with different facing solutions.

What are the foundational requirements for constructing a metal building?

The foundational requirements for constructing a metal building include a proper site evaluation, soil testing, creating a solid and level base using materials like gravel or concrete, and ensuring accurate anchorage to withstand environmental pressures.

How is electrical wiring installed in a metal structure?

Electrical wiring in a metal structure is installed through a process of routing conduit – a protective tube for the wiring – within the interior walls of the structure, and attaching electrical boxes to the metal studs.

What factors influence the longevity of metal building homes?

The longevity of metal building homes is influenced by factors such as the quality of construction materials, the expertise of the construction team, regular maintenance, and the environmental conditions where the building is situated.

Recap