Polymers’ physical and chemical properties significantly impact their use in building materials. pH affects the strength of adhesives that bind different components together. Meanwhile, solubility affects durability and resistance to environmental conditions.

Polymers are a type of material that has been used in building materials for decades. They are often chosen for their strength, durability, and cost-effectiveness.

However, polymers’ physical and chemical properties can also play an important role in their use in construction. In this blog post, we will explore how the pH and solubility of polymers affect their use as building materials.

This blog looks at how these properties are manipulated. They are used to create materials with desired characteristics. Furthermore, we’ll also explore the drawbacks to consider when using polymers in construction projects.

Polymers’ physical and chemical properties, such as their pH and solubility, significantly impact their use in building materials. For instance, the pH of a polymer affects its ability to bond with other materials. Additionally, its solubility can determine how it interacts with water or other liquids.

Certain polymers may be more resistant to heat or chemicals than others, making them more suitable for specific applications.

Key takeaways:

- Polymers’ pH affects adhesion and stability in building materials.

- Solubility determines mixing capabilities and resistance to harsh conditions.

- Polymers must be compatible with other materials in construction.

- Weather conditions can impact polymer properties in construction.

- Polymer flexibility enhances structural integrity and durability.

pH

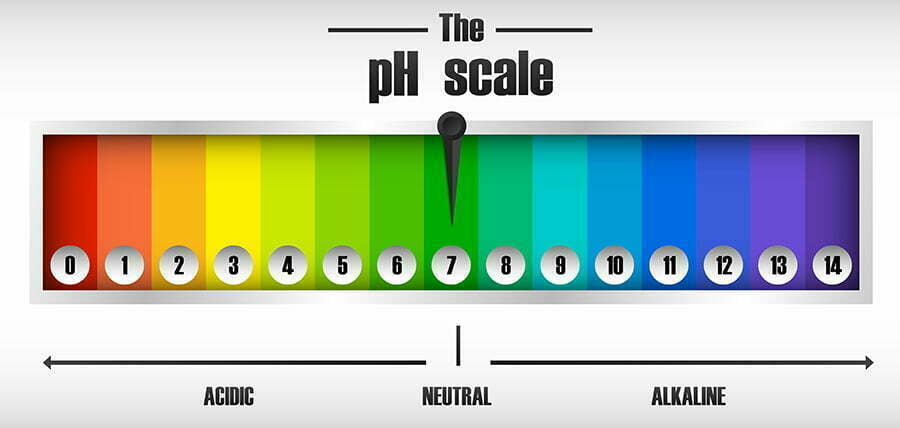

The pH of a polymer is an important factor in determining its suitability for use in building materials. The pH of a material is a measure of its acidity or alkalinity. It can range from 0 (very acidic) to 14 (very alkaline).

Polymers with higher pH values are more stable and resistant to degradation, making them better suited for building materials. On the other hand, polymers with lower pH values are more susceptible to damage from environmental factors. This includes moisture and temperature changes.

Therefore, it is important to consider their pH levels. This is to know if the material can withstand the conditions they will encounter during their lifetime.

Solubility

Solubility measures how easily a substance can be dissolved in another substance.

This property affects their use in building materials because it determines whether or not they can be mixed with other substances and form a homogenous solution.

For example, if a polymer is highly soluble, it can be used as an adhesive for bonding two surfaces together; however, if it has low solubility, it may not be suitable for this purpose.

Some polymers are more resistant to degradation when exposed to certain chemicals than others due to their solubility properties; this makes them ideal for use in waterproofing applications where resistance against harsh environmental conditions is necessary.

Effect in Building Materials

Building materials are used to construct buildings, structures, and other objects. They can be natural or artificial and include wood, concrete, stone, metal, glass, plastics, and composites.

Building materials must be strong enough to withstand the weight of a structure while also being able to resist environmental factors such as wind and rain.

The physical properties of building materials are important for their use in construction; however, chemical properties can also play an important role.

Chemical properties refer to how a material reacts with other substances when exposed to certain conditions. For example, polymers have different pH levels, which affect their solubility in water or other liquids.

More soluble polymers will be easier to work with during construction because they can be mixed into solutions that make them easier to shape or form into desired shapes for building purposes.

Additionally, some polymers may react with certain chemicals, which could cause them to degrade over time if not properly protected from these elements during construction.

Knowing the chemical properties of polymers is essential for ensuring that they will perform well when used in building materials applications.

Compatibility of Polymer Materials With Other Construction Materials

When considering the use of polymer materials in construction, it is crucial to assess their compatibility with other construction materials. The interaction between polymers and different substances can significantly impact the overall performance and durability of building structures.

One important aspect to consider is the adhesion properties of polymers when used alongside other materials such as metals, concrete, or wood. Proper adhesion ensures a strong bond between different components, enhancing structural integrity.

Adhesive strength can be influenced by factors like surface preparation techniques and chemical compatibility between the polymer and substrate.

Thermal expansion coefficients should be taken into account when combining polymers with other construction materials. Different substances expand or contract at varying rates under temperature changes.

Mismatched expansion coefficients may lead to stress concentrations or even material failure over time.

Chemical resistance is another critical factor for assessing compatibility in building applications involving exposure to harsh environments or chemicals such as acids, alkalis, solvents etc. Polymers that are resistant to specific chemicals will maintain their physical properties over extended periods without degradation.

Impact of Weather Conditions On Polymer Properties in Construction

Polymers are sensitive to temperature changes, moisture levels, UV radiation, and other environmental factors. Extreme heat can cause polymers to soften or deform, compromising their structural integrity.

On the other hand, extreme cold temperatures can make polymers brittle and prone to cracking.

Moisture is another critical factor that affects polymer properties in construction materials. Excessive moisture absorption can lead to dimensional changes such as swelling or warping of the material over time.

This not only compromises its appearance but also weakens its mechanical strength.

UV radiation from sunlight is known for causing degradation in many types of polymers used in building materials. Continuous exposure to UV rays leads to photochemical reactions that break down chemical bonds within the polymer structure, resulting in discoloration, loss of strength and stiffness.

To mitigate these weather-related challenges faced by polymers used in construction applications various strategies are employed such as incorporating additives like stabilizers or using protective coatings on surfaces exposed directly to weather elements.

Role of Polymer Flexibility in Structural Integrity

Unlike rigid materials, such as metals or ceramics, polymers have the ability to deform under stress and return to their original shape once the stress is removed. This property allows them to absorb and distribute forces more effectively, reducing the risk of cracks or fractures.

In construction applications, polymer flexibility helps enhance durability by providing resistance against impacts and vibrations. For example, in earthquake-prone areas where buildings need to withstand ground motion, flexible polymer-based materials can help dissipate energy and prevent catastrophic failures.

Moreover, polymer flexibility also contributes to improved performance during temperature fluctuations. As temperatures rise or fall, structures made with flexible polymers can expand or contract without significant damage.

This thermal expansion capability reduces the likelihood of material failure due to thermal stresses.

Innovation Trends in Polymer Applications in Building Materials

These innovations have opened up new possibilities for construction projects, offering improved performance and sustainability. One notable trend is the development of high-performance polymer composites that combine different materials to create stronger and more durable structures.

These composites often incorporate fibers such as carbon or glass to enhance strength while maintaining flexibility.

Another area of innovation is the use of polymer-based coatings and sealants for enhanced protection against environmental factors like moisture, UV radiation, and chemical exposure. These coatings can extend the lifespan of buildings by preventing corrosion or degradation.

Researchers are exploring ways to improve energy efficiency through innovative polymer applications. For example, smart polymers with shape memory properties can be used in windows or facades to regulate temperature by responding dynamically to external conditions.

Furthermore, sustainable practices are gaining traction within the construction industry. Polymers derived from renewable sources such as plant-based biopolymers offer an eco-friendly alternative without compromising on performance characteristics.

Recycling and Environmental Aspects of Polymer-Based Construction Materials

One significant advantage is the ability to recycle these materials, reducing waste and promoting sustainability in the construction industry.

Recycling polymers involves collecting used or discarded polymer-based products and processing them into new raw materials. This process helps conserve natural resources by reducing the need for virgin materials.

Recycling reduces energy consumption and greenhouse gas emissions associated with manufacturing new polymers from scratch.

The environmental aspects of using recycled polymer-based construction materials extend beyond resource conservation. By diverting these products from landfills, we can minimize landfill space requirements and reduce pollution risks such as leaching of harmful chemicals into soil or water sources.

Furthermore, incorporating recycled polymers in building projects can contribute to achieving green building certifications like LEED (Leadership in Energy and Environmental Design). These certifications recognize sustainable practices that prioritize energy efficiency, waste reduction, and environmentally friendly material choices.

It’s worth noting that while recycling offers numerous benefits for polymer-based construction materials’ lifecycle management, it’s essential to ensure proper sorting at the source to maximize recyclability potential. Proper disposal methods should be followed so that only clean plastics are sent for recycling without contamination from other non-recyclable substances.

Considering the recyclability aspect when selecting polymer-based construction materials not only supports sustainable practices but also contributes towards a circular economy where resources are conserved through reuse rather than disposal.

FAQ

How are the physical properties of polymers affected by their structure?

The physical properties of polymers, such as their strength, flexibility, responsiveness to temperature, and even their capacity to conduct electricity are inherently determined by their shape and structure.

What are the physical and chemical properties of polymers?

Polymers exhibit a range of physical properties such as tensile strength, melting point, boiling point, hardness, heat and electrical conductivity, refractive index, elasticity, crystallinity, permeability, and others; chemically, natural polymers are typically non-toxic, biodegradable, and stable.

What are the uses of polymers as building materials?

Polymers are used as building materials for flooring, windows, cladding, rainwater solutions, piping, membranes, seals, glazing, insulation, and signage, among other things.

What are the factors affecting the physical properties of polymers?

The physical and mechanical properties of polymers, including transition temperature, viscosity, strength, stiffness, and toughness, are significantly influenced by their molecular weight.

How do polymers contribute to sustainable construction initiatives?

Polymers contribute to sustainable construction initiatives by allowing for materials reuse and recycling, reduction in construction waste, enhanced energy efficiency, and extended lifespan of structures.

What are some examples of advanced polymer-based construction materials and their advantages?

Advanced polymer-based construction materials include Self-Healing Concrete that extends the building’s life by repairing its own cracks, and Polycarbonate Panels offering thermal insulation, durability, and UV resistance.

What challenges need to be addressed in the wider adoption of polymers in construction?

The wider adoption of polymers in construction faces challenges such as cost-effectiveness, durability, fire resistance, environmental impact and standardization regulations.

Recap