This article offers a straightforward explanation of polymers and their significance in various applications, particularly in the construction industry.

Key takeaways:

- Polymers are large molecules with repeating structural units.

- They can be natural or synthetic, with diverse properties and applications.

- Polymers can be linear, branched, or crosslinked.

- Common polymers include PE, PP, PVC, PS, and nylon.

- Polymers are used in insulation, coatings, adhesives, flooring, piping, concrete reinforcement, and roofing.

What Is Polymer?

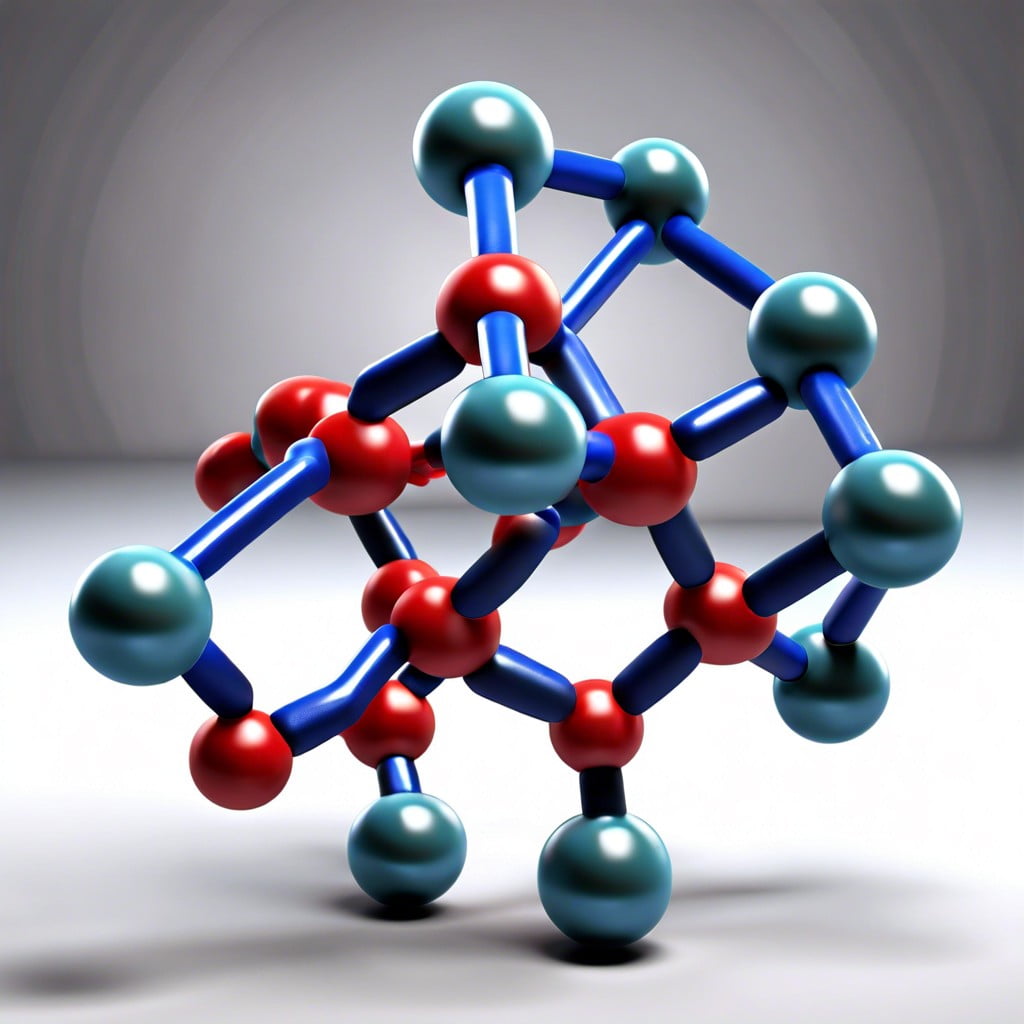

Polymers are large molecules composed of repeating structural units, typically connected by covalent chemical bonds. Think of them like a train made up of many identical or similar cars – these ‘cars’ are the small, repeating units known as monomers, and the entire train represents the polymer. These monomeric units can be simple — like beads on a string — or complex, branching off like trees from a trunk. Monomers bind together through chemical reactions, often leading to long chains that determine the physical properties of the polymer.

The molecular structure can greatly vary, leading to a vast range of material characteristics. Some polymers boast incredible strength and durability, while others are known for their flexibility or elasticity. These materials can be synthetic, such as plastic and nylon, or natural, like rubber and cellulose. This inherent versatility makes polymers fundamental to countless products and industries, serving as the building blocks for materials ranging from plastic containers to high-tech aerospace components.

Structure

Polymers are large molecules composed of repeating structural units called monomers, which are covalently bonded to form long chains. Each polymer has a unique structure, determining its physical and chemical properties. The monomers can be identical, or they can be a combination of different types, leading to copolymers with varied characteristics.

These chains can be arranged in several configurations:

- Linear polymers have monomers joined end to end in single lines.

- Branched polymers have side chains attached to the main chain.

- Crosslinked polymers have chains that are connected by links between the chains.

The length of the chains and the nature of the crosslinking between chains can significantly impact the polymer’s flexibility, toughness, and melting point. Understanding a polymer’s structure is key to predicting its behavior in various applications, from construction materials to everyday household products.

Types of Polymers

Polymers come in various forms, each with unique properties that suit different applications. They are primarily categorized based on their origin and structure.

1. Natural Polymers: These occur in nature and include proteins, cellulose, and rubber. They are essential for biological functions and are also used in various industrial applications.

2. Synthetic Polymers: Created through chemical processes, these polymers include plastics, synthetic rubber, and nylon. They are widely used in manufacturing due to their adaptability and durability.

3. Thermoplastics: These polymers become moldable at high temperatures and solidify upon cooling. Examples include polyethylene and polystyrene, commonly used in packaging and consumer products.

4. Thermosetting Polymers: Once set, these polymers do not melt. They have a rigid, three-dimensional network of bonds, making them ideal for high-heat applications. Examples are epoxy resin and melamine.

5. Elastomers: Possessing elasticity, these polymers can stretch and return to their original shape. Rubber is a prime example, crucial in tire manufacturing.

6. Fibers: With high tensile strength, these polymers are suitable for textiles. Polyester and nylon are examples, extensively used in clothing and home furnishings.

Common Examples

Polymers surround us in everyday life, from natural to synthetic examples. Some prevalent ones include:

–Polyethylene (PE): You encounter PE when using plastic bags and bottles. It is favored for its durability.

–Polypropylene (PP): Found in automotive parts and food containers, PP is noted for its resistance to wear and high temperatures.

–Polyvinyl Chloride (PVC): PVC is used in plumbing and medical devices, appreciated for its versatility and robustness.

–Polystyrene (PS): Commonly seen in packaging foam and disposable tableware, PS is lightweight and cost-effective.

–Nylon: A well-known fabric in clothing and carpets, nylon is recognized for its strength and elasticity.

These polymers are pivotal in industrial and domestic applications, showcasing a wide range of properties and functionalities.

Applications

In the construction industry, polymers play a pivotal role in enhancing building performance and durability. They are integrated into a variety of applications, showcasing their versatility.

1. Insulation: Spray foam made from polyurethane provides high-performance insulation, significantly improving energy efficiency by filling gaps and reducing air leakage.

2. Paints and Coatings: Acrylic and epoxy-based polymers offer protective and decorative finishes for surfaces, guarding against moisture, decay, and UV radiation.

3. Adhesives and Sealants: Silicone and polyurethane sealants are used for their strong bonding capabilities and flexibility, essential for joints and fixtures.

4. Flooring: Polymer composites, such as vinyl or epoxy resins, are used in flooring systems for their durability, resistance to wear, and ease of maintenance.

5. Piping Systems: Polyvinyl chloride (PVC) and high-density polyethylene (HDPE) pipes are widely used for their strength, chemical resistance, and low cost.

6. Concrete Reinforcement: Fibers made from polymers like polypropylene are added to concrete to reduce cracking and improve tensile strength.

7. Roofing Materials: Thermoplastic polyolefin (TPO) and polyvinyl chloride (PVC) membranes are used in roofing for their longevity and ability to withstand extreme weather conditions.

Each of these examples demonstrates the critical influence polymers have on modern construction methods and materials, providing solutions that enhance both the functionality and sustainability of built environments.

FAQ

What is a polymer simple definition?

A polymer is a large molecule composed of many repeated subunits, known as monomers, chemically bonded together in a chain-like structure.

What are the examples of polymers?

Examples of polymers include synthetic variants like nylon, polyethylene, polyester, Teflon, and epoxy, while naturally occurring polymers encompass silk, wool, DNA, cellulose, and proteins.

Is polymer just plastic?

No, a polymer is not just plastic; while all plastics are polymers, not all polymers are plastics, as there are natural polymers, such as cellulose, that are not classifiable as plastics.

How are polymers used in construction and infrastructure?

Polymers are used in construction and infrastructure as protective coatings for surfaces, sealants, adhesives, concrete additives, insulation materials, piping, wiring, and in the manufacturing of sturdy yet lightweight structural components.

What are the main differences between natural and synthetic polymers?

Natural polymers originate from nature and are often biodegradable, like cellulose and silk, while synthetic polymers are man-made, more durable and versatile, such as plastics and resins.

What are some of the main advantages and limitations of polymers in construction?

The main advantages of polymers in construction are their light weight, durability, resistance to moisture and chemicals, and versatility, while their limitations include susceptibility to UV damage, thermal expansion, and environmental issues related to their production and disposal.

Recap