Discover how cross-linked polymers create super-strong materials that revolutionize construction.

Key takeaways:

- Cross-linked polymers have strong, durable, and elastic properties.

- Cross-linking occurs through chemical bonding and heat or radiation.

- Cross-linked polymers have characteristics such as durability, chemical resistance, thermal stability, stiffness, and shape memory.

- Applications in construction include insulation, flooring, roofing, and adhesives.

- Limitations include difficulty in recycling, lack of flexibility, higher cost, and sensitivity to high temperatures.

What Is Cross-Linked Polymer?

Imagine your favorite toy made of rubber bands. Now, instead of each band doing its own thing, they are all tied together at various points. This is essentially what happens with cross-linked polymers.

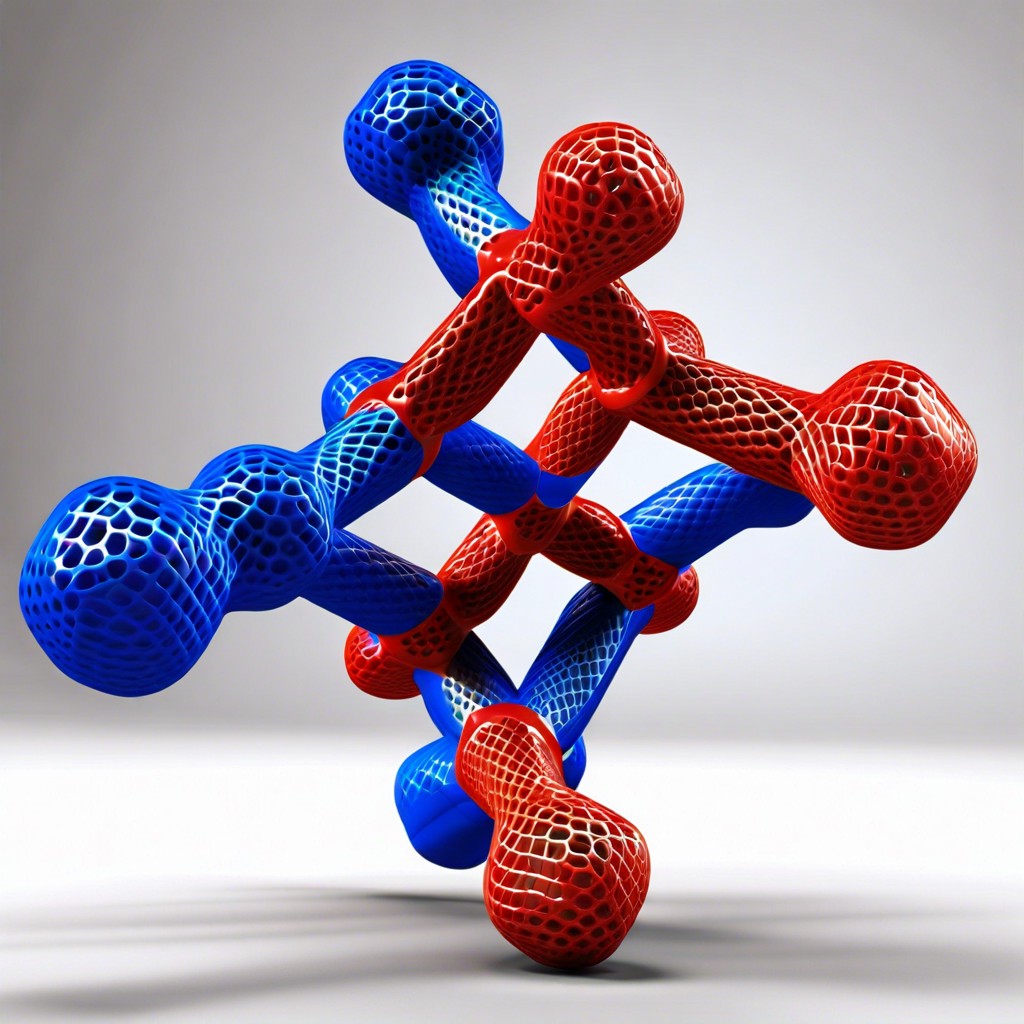

In technical terms, these polymers have their long molecular chains connected by links. These links act like bridges, turning the material into a three-dimensional network. Think of it as a super organized net.

Cross-linking makes the polymer less sticky and more elastic. It’s like giving the material a backbone, which makes it stronger and more durable.

The tricky part is getting the right amount of linking. Too much, and the polymer becomes too rigid. Too little, and it’s back to being floppy. The sweet spot makes it perfect for all sorts of applications, especially in construction.

Mechanism of Cross-Linking

Imagine polymers as long noodles. Cross-linking is like turning those noodles into a lasagna! When it’s cross-linked, the ‘noodles’ form bonds at various points, connecting in a way that turns the whole structure much sturdier.

Here’s how it works:

– Chemical Bonding: Special chemicals called cross-linkers create bonds between the polymer chains. Think of them as tiny matchmakers.

– Heat or Radiation: Sometimes, heat or radiation helps activate the cross-linkers. It’s a bit like putting bread in a toaster, making everything firmer and more rigid.

– Reversible vs. Irreversible: Some cross-links can be undone, like Velcro. Others are permanent, like superglue. This determines how the cross-linked polymer can be used.

So next time you see a strong, durable material in construction, just remember, it’s because of those ‘lasagna noodles’ all bonded together.

Characteristics and Properties

Alright, let’s talk about the coolest features of cross-linked polymers.

Firstly, think about durability. These guys are the superheroes of the polymer world. Thanks to their interlinked structure, they stand tough against wear and tear.

Next, let’s chat about chemical resistance. Cross-linked polymers laugh in the face of corrosive chemicals. Really, they’re the hazmat suits of materials.

Then, there’s thermal stability. These polymers can handle the heat without breaking a sweat. Imagine a material staying solid and functional in both a bakery and a freezer. Neat, right?

Oh, and don’t forget stiffness and strength. Cross-linked polymers are like the bodybuilders of the material world. They can take a lot of weight and pressure without giving in.

And here’s a fun one – shape memory. Bend it, twist it, stretch it? No problem. It snaps back to its original shape like it’s got some sort of built-in GPS.

So, in short, cross-linked polymers have durability, chemical resistance, thermal stability, strength, and even a little bit of shape-shifting magic. They’re like the material equivalent of a Swiss Army knife – handy and versatile!

Applications in Construction

Imagine you could make your house or office an impenetrable fortress but without turning it into a creepy castle. That’s where cross-linked polymers step in.

First up, insulation. Cross-linked polyethylene (PEX) pipes not only transport water efficiently, but they’re excellent insulators, keeping your hot water hot and your cold water cold. It’s like having a thermos but for your plumbing.

On to flooring. Ever heard of epoxy resins? They’re used to create those shiny, durable floors you see in garages and fancy showrooms. They’re tough cookies, resistant to chemicals, stains, and general wear-and-tear.

Roofing can also benefit. Think waterproofing membranes. These membranes ensure your roof has an extra layer of protection against leaks. It’s like giving your roof a raincoat that’s fashion-forward and functional.

And don’t forget adhesives. Cross-linked polymers make super strong glues that hold building materials together better than a toddler clings to their favorite toy.

So, whether it’s pipes, floors, roofs, or sticking things together, cross-linked polymers are indispensable in keeping your construction projects solid and sleek.

Limitations and Challenges

While cross-linked polymers bring a lot to the construction table, they aren’t without their quirks. First off, they can be a bit tricky to recycle. Picture trying to undo a complex knot; once those polymers are cross-linked, they’re more stubborn than a Monday morning.

Also, flexibility isn’t their strong suit. Need something bendy? Well, these polymers are more like rigid gym teachers demanding perfect form. They offer strength but don’t expect them to do yoga.

Cost can also be a sticking point. The fancy chemistry involved in cross-linking can make these materials pricier. Finally, let’s not forget temperature sensitivity. High heat? They might start to lose their cool—literally.

Recap