Discover how cationic polymers play a pivotal role in construction applications, improving materials from concrete to coatings.

Key takeaways:

- Cationic polymers are positively charged and can form strong bonds.

- They have diverse applications in construction, water treatment, and medicine.

- In water treatment, they attract and clump together contaminants.

- In medicine, they aid in drug delivery, gene therapy, and wound healing.

- Their environmental impact varies, and efforts are being made to improve degradability.

Definition of Cationic Polymers

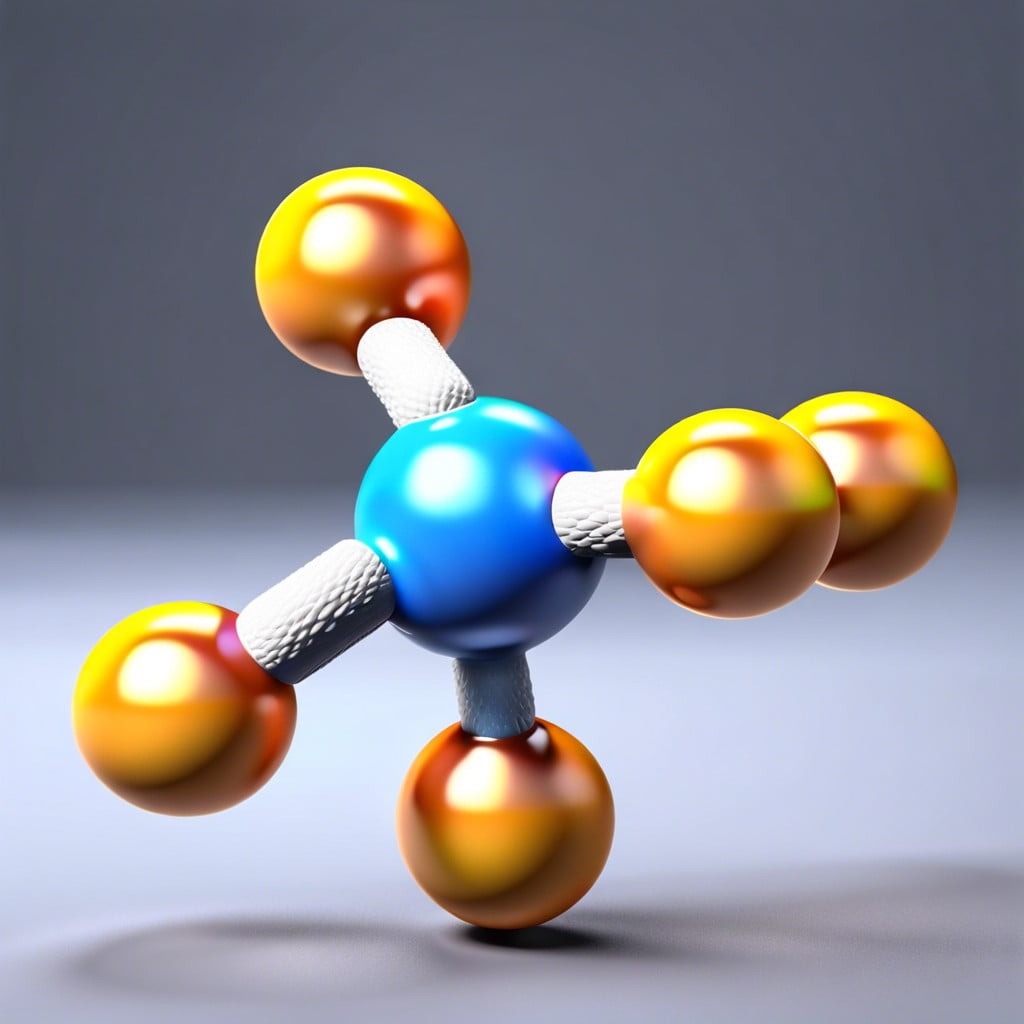

Imagine tiny magnets in the world of plastics, and you’ll get the picture of cationic polymers. They’re a family of polymers that carry a positive charge due to the presence of cations, which are positively charged ions. This positive disposition makes them sociable with negatively charged substances, allowing them to form strong bonds.

They’re often compared to chameleons for their ability to adapt and perform in various environments. These polymers are like the life of the party in a chemical reaction, attracting all sorts of guests – from dirt particles to harmful bacteria – making them incredibly useful in a wide range of applications.

Think of them as the superheroes of the polymer gang: just as a superhero uses their power for good, cationic polymers use their positive charge to tackle unwanted elements in products and processes.

Chemical Structure and Properties

Cationic polymers are a family of polymers positively charged at certain pH levels. Picture them like a group of friends at a party, positively glowing and ready to bond with anyone with a negative vibe, or in this case, negatively charged particles.

The chemical structure of these polymers includes a backbone with attached groups called quaternary ammonium groups. These are the life of the party, holding the positive charge that makes the polymer cationic. Think of them like magnets at a scrapyard, attracting metals with a different charge.

This positive charge is what gives these polymers their superpower in various applications. For instance, in water treatment, they act like bouncers, clumping together unwanted particles so they can be more easily removed from the scene. They work efficiently and fast, making them ideal in situations where time is of the essence.

Moreover, their solubility in water and ability to form films make them versatile in the construction business. Imagine them as the versatile multitool in your drawer that can tackle diverse tasks without breaking a sweat.

In essence, the chemical structure and properties of cationic polymers give them the power to form strong bonds with oppositely charged materials, behave predictably in various environments, and make them a valuable asset in both industrial and medical fields.

Applications in Water Treatment

Cationic polymers are the unsung heroes of the water treatment theater. Picture these polymers as tiny magnets, attracting negatively charged particles, such as dirt, organic materials, and certain microbes, in water. Their positive charge acts like a beacon, pulling in contaminants to form larger groups, known as flocs. These flocs are easier to remove because, like a snowball rolling downhill, they pick up size and speed, becoming too big to stay dissolved in water.

In the water purification process, these cationic polymers are added during the flocculation stage. Their role? To speed up the process of clumping together suspended particles so that our water becomes clearer faster. It’s like adding a supercharged coagulant that works wonders in making murky water crystal clear.

Furthermore, they do an excellent job in reducing water turbidity, which is a fancy way of saying they help make cloudy water bright and transparent. It’s almost as if they give water a spa treatment, removing all the impurities for a fresh and clean result.

Unlike their neutral or anionic counterparts, cationic polymers have a unique affinity for many impurities found in wastewater, making them a top choice for industrial water treatment as well. In a nutshell, these polymers are like bouncers at a club, ensuring unwanted particles don’t make it into our clean water.

So, the next time you enjoy a glass of water or swim in a pool, there’s a good chance cationic polymers played a part in making that experience possible. They might be invisible to the eye, but their impact is crystal clear.

Biomedical Applications

Cationic polymers are like the Swiss Army knives of the biomedical field – multi-functional and incredibly handy. Their positive charge is the secret sauce that makes them adept at interacting with negatively charged biological membranes. This trait has paved the way for several medical marvels.

First off, we’ve got drug delivery. These polymers can cling onto drugs, ensuring they reach their intended site without going on a wild ride through the body. This precision reduces side effects and improves efficacy. Imagine them as your drugs’ personal Uber, providing a direct route to their destination.

Then there’s gene therapy. Cationic polymers can safely wrap around genetic material and protect it during its journey into cells. Think of them as the protective bubble wrap for fragile genetic parcels, ensuring they’re delivered intact.

And let’s not forget tissue engineering. These polymers help scaffold tissues, giving cells a cozy place to settle down and grow. It’s like setting up a tent for your cells to camp out while they regenerate.

Lastly, they also star in wound healing, acting like a ‘sticking plaster’ that not only covers up but actively helps wounds to heal. They’re the supportive friends we all need when we’re a bit rough around the edges.

There you have it, cationic polymers in a nutshell – or should we say, in a healing gel?

Environmental Impact and Degradability

Cationic polymers, like any other synthetic materials, leave a footprint on the environment. Picture these polymers as guests at a party thrown by Mother Nature. Some are the kind that clean up after themselves, causing little to no fuss. Others, not so much, lingering long after the music has stopped.

When it comes to degradability, these polymers can be a mixed bag. For instance, those derived from natural sources such as cellulose or starch tend to break down more readily, with microorganisms in the environment acting like little recycling workers. On the flip side, petroleum-based polymers may stick around much longer, taking extended vacations in landfills or in the ocean.

Researchers are constantly on the prowl for innovative tweaks that can make cationic polymers more eco-friendly. Think of them as environmental tailors, working to adjust the lifespan of these materials so that they degrade on a more polite timeline. By introducing biodegradable elements into the polymer chain, they’re crafting materials that get with the green program, breaking down after fulfilling their duty without overstaying their welcome.

To sum up, while cationic polymers bring a host of benefits to the table, it’s crucial to balance their conveniences with their environmental impact. It’s a bit like a see-saw – finding that sweet spot where utility and sustainability can happily coexist.

Recap