Discover how carbohydrate polymers are created and their vast applications in diverse fields in this informative article.

Key takeaways:

- Carbohydrate polymers are large, complex molecules made up of sugar units.

- They can be classified into different categories based on their structure and components.

- Carbohydrate polymers have diverse applications in medicine, construction, textiles, food, and agriculture.

- They have a lower environmental impact compared to synthetic polymers.

- Ongoing research aims to enhance their properties and biodegradability for future applications.

Definition and Classification of Carbohydrate Polymers

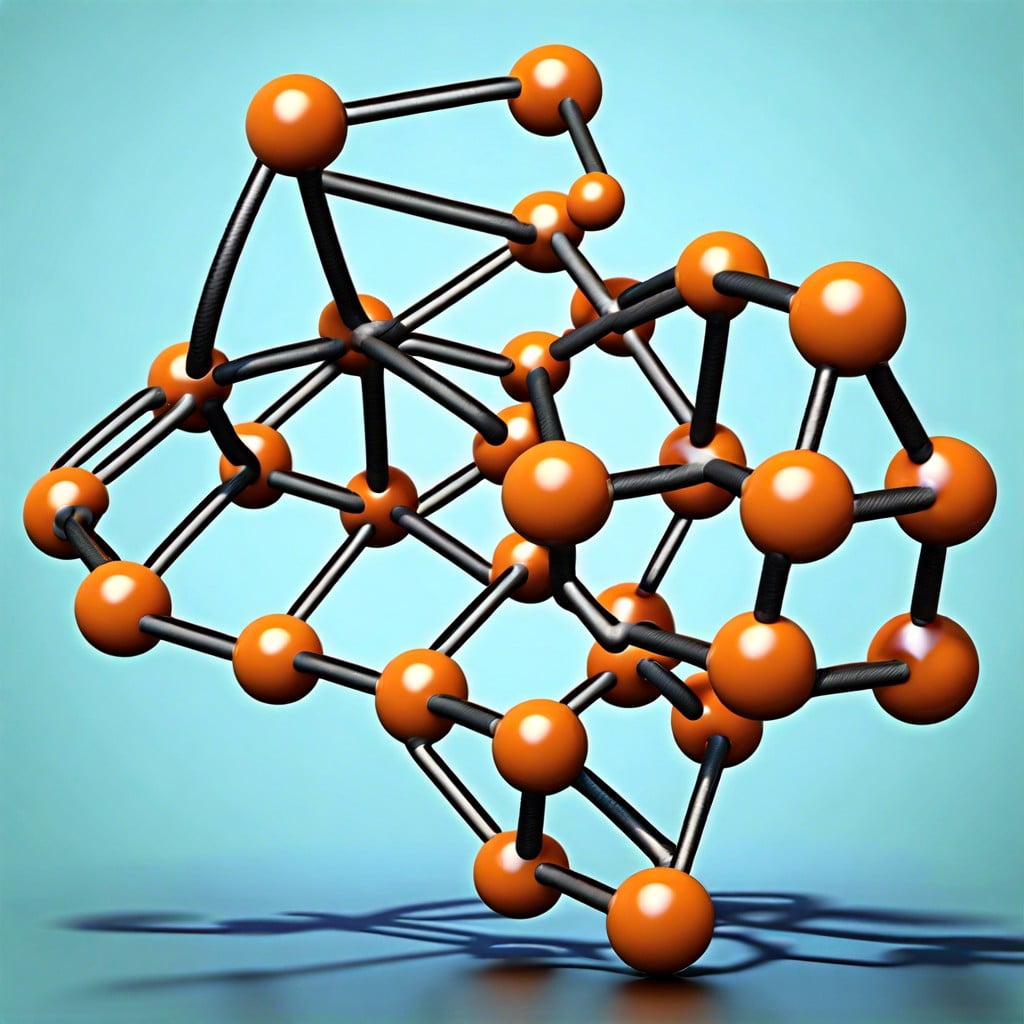

Carbohydrate polymers, commonly known as polysaccharides, are large, complex molecules made up of long chains of monosaccharide units. These units are sugar molecules, such as glucose, that are joined together by glycosidic bonds. The way these sugars link, as well as the length of the chain, can vary greatly, affecting the polymer’s properties and functions.

Based on their structure and components, carbohydrate polymers fall into several categories:

- Homopolysaccharides: These are composed of only one type of monosaccharide. Examples include cellulose, which is made exclusively of glucose units, and chitin, consisting entirely of N-acetylglucosamine.

- Heteropolysaccharides: These consist of two or more different kinds of monosaccharides. Examples are hyaluronic acid and heparin, which play critical roles in biological processes.

- Linear polysaccharides: These have monosaccharides linked in a straight chain, such as cellulose, which contributes to the strength and rigidity of plant cell walls.

- Branched polysaccharides: These have side chains branching off the main chain, such as glycogen, which serves as a storage form of energy in animals.

This classification provides a foundation to understand the diverse roles carbohydrate polymers play in nature and their potential applications.

Chemical Structure of Carbohydrate Polymers

Carbohydrate polymers, or polysaccharides, are macromolecules composed of sugar units, or monosaccharides, linked together by glycosidic bonds. These sugar units can be identical, such as in starch, or different, as seen in hemicellulose.

There are a few key points to understand about their chemical structure:

- Monosaccharide Building Blocks: The basic structure starts with simple sugars like glucose, fructose, or galactose. These monomers form chains that define the type of carbohydrate polymer.

- Glycosidic Linkages: These are the bonds that connect monosaccharides. They determine the polymer’s stability, solubility, and resistance to enzymatic breakdown.

- Chain Branching: Some polysaccharides, like glycogen, are highly branched, while others, like cellulose, are mostly linear. Branching influences the polymer’s physical properties and functionality.

- Molecular Weight: This refers to the size of the polymer, i.e., the number of monosaccharides in a chain. High molecular weight usually translates to increased viscosity and strength.

- Degree of Polymerization: This term describes the number of monosacrylic residues in the chain. It directly affects the polymer’s mechanical properties and its application potential in construction materials.

These characteristics result in diverse polysaccharides with unique properties, from the rigid structure of cellulose, which provides strength to plant cell walls, to the gel-forming ability of pectin used in various building material applications.

Applications of Carbohydrate Polymers

Carbohydrate polymers are versatile materials in various industries due to their biodegradability and sustainability.

In the medical field, they are used for drug delivery systems. Polysaccharides create biocompatible and biodegradable vehicles that can release medication over a controlled period.

Construction materials also benefit from these polymers. They serve as binders and adhesives, offering an eco-friendly alternative to synthetic options.

In textiles, carbohydrate polymers improve fabric properties, such as wrinkle resistance and flame retardancy, without using toxic chemicals.

The food industry uses them as thickeners, gelling agents, and stabilizers, enhancing the texture and shelf life of products.

Agriculture utilizes carbohydrate polymers for enhancing soil quality and water retention, which can lead to reduced water usage.

These applications exemplify the multifaceted roles carbohydrate polymers play in advancing sustainable practices across different sectors.

Environmental Impact of Carbohydrate Polymers

Carbohydrate polymers, primarily sourced from renewable plant materials, offer a significant advantage in terms of environmental impact compared to their synthetic counterparts. They are typically biodegradable, breaking down into natural substances like water and carbon dioxide when decomposed by microorganisms. This means that products made from these polymers are less likely to contribute to the accumulation of plastics in landfills and oceans.

Additionally, the production of carbohydrate polymers often requires less energy and results in lower greenhouse gas emissions. Since plants absorb carbon dioxide during their growth, using them as a source for materials can contribute to a reduction in the overall carbon footprint of materials. The ability to cultivate the raw materials for carbohydrate polymers on a sustainable basis also helps in promoting agricultural practices that are less harmful to the ecosystem.

However, it is important to consider the full life cycle impact of these materials. While degradation is a positive aspect, the conditions under which carbohydrate polymers degrade is crucial. In environments lacking the necessary conditions for biodegradation, these materials could persist as long as traditional plastics. Responsible disposal and industrial composting facilities are vital to realizing their environmental benefits.

In summary, while carbohydrate polymers present a more eco-friendly alternative in materials science, their actual impact is intertwined with factors such as manufacturing practices, product design, and end-of-life disposal strategies.

Future Perspectives and Developments in Carbohydrate Polymer Technology

Advancements in technology continuously open new frontiers for carbohydrate polymers. Researchers are working to enhance their properties, such as durability and biodegradability, to better meet specific industry needs.

1. Increased Durability: By modifying the molecular structures, scientists aim to produce carbohydrate polymers that are more resistant to harsh environmental conditions, extending their lifespan for various construction applications.

2. Smart Carbohydrate Polymers: The development of stimulus-responsive polymers that can change properties in response to environmental cues is on the horizon, offering innovative uses in smart buildings.

3. Improved Biodegradability: Efforts are being made to ensure that these polymers break down more efficiently after use, reducing their environmental impact and facilitating their integration into a circular economy.

Through these initiatives, carbohydrate polymers are set to offer more sustainable and versatile materials for the construction industry in the coming years.

FAQ

What is the polymer of a carbohydrate?

The polymer of a carbohydrate is either a disaccharide, which has two monomers, or a polysaccharide, containing multiple monomers.

What is the impact factor of carbohydrate polymers?

The impact factor of carbohydrate polymers for the year 2022 is 11.2.

Is cellulose a carbohydrate polymer?

Yes, cellulose is a carbohydrate polymer as it consists of hundreds to thousands of linked glucose molecules.

What is the bond of carbohydrates?

The bond formed between two carbohydrate molecules, specifically between two monosaccharides, is known as a glycosidic bond.

How are carbohydrate polymers used in construction materials?

Carbohydrate polymers, like cellulose, are used in construction materials to enhance strength, durability, and sustainability.

What are the properties that make cellulose a valuable carbohydrate polymer in construction?

Cellulose, a valuable carbohydrate polymer in construction, is prized for its tensile strength, biodegradability, non-toxicity, low cost, and abundance in nature.

Why is the bond structure significant in function and application of carbohydrate polymers?

The bond structure in carbohydrate polymers is significant as it determines the polymer’s physical properties and chemical reactivity, influencing its suitability for particular applications in areas like construction, medical therapeutics, and biodegradable materials.

Recap