Selecting the best insulation for metal buildings is crucial because it significantly influences the overall energy efficiency, structural integrity, and comfort level of your structure.

Insulation is a crucial aspect of metal building construction, ensuring energy efficiency and temperature regulation. The best types of insulation for a metal building include spray foam, fiberglass, and rigid board.

Each type offers unique benefits: spray foam provides high thermal resistance and air sealing; fiberglass is cost-effective and non-flammable; rigid board, while more expensive, offers high R-value (insulating power) and excellent moisture resistance.

In this article, we delve into the specifics of these insulation types, their application methods, pros and cons, and how to choose the one that fits your building’s needs perfectly. So, whether you’re insulating a new metal building or retrofitting an existing one, we’ve got you covered with all the details you need to make an informed decision.

Key takeaways:

- Spray foam, fiberglass, and rigid board are the best insulation types for metal buildings.

- Benefits of insulation include temperature regulation, energy efficiency, condensation control, noise reduction, and longevity of the structure.

- R-Values measure resistance to heat flow, while U-Values measure the rate of heat transfer.

- Local code requirements, such as R-Value and Fire Resistance Ratings, should be considered when choosing insulation.

- The amount of insulation needed depends on climate, building usage, and energy code requirements.

Benefits of Insulating Your Metal Building

Insulation serves a dual function in metal buildings, enhancing comfort levels while also promoting energy efficiency. Let’s explore these benefits:

1. Temperature Regulation: Insulation effectively maintains a stable temperature, ensuring warmth in winter and coolness in summer.

2. Energy Efficiency: By controlling heat transmission, insulation reduces the energy load on heating and cooling systems, thus lowering utility bills.

3. Condensation Control: By reducing the temperature differential between the outside and the interior of the building, insulation helps reduce condensation, avoiding potential damage to the structure.

4. Noise Reduction: Insulation serves as an acoustic barrier, diminishing external noises and providing a quiet environment within the building.

5. Longevity of the Structure: Insulation can help protect metal buildings from harmful environmental factors, extending the durability and lifespan of the structure.

R-Values and U-Values for Metal Building Insulation

R-Values measure the resistance of an insulating material to conductive heat flow. A higher R-Value indicates a greater resistance to heat transfer, thus providing superior insulation. Conversely, U-Values measure the rate of heat transfer through a material. An insulating material with a lower U-Value indicates less heat transfer and better insulation properties.

Key points to remember are:

- R-Values are additive, meaning if multiple layers of insulation are used, you can simply add the R-Values of each layer to get the total insulation value.

- The optimal R-Value varies depending on the climate. In colder climates, higher R-Values are beneficial, whereas in hot climates, lower values are sufficient.

- Metal building insulation should have a lower U-Value, as this means less heat is transferred due to conduction, convection, or radiation.

- Each type of insulation will have both R-Values and U-Values listed so you can contrast and compare, ensuring you choose the right insulation for your metal building based on your specific needs.

Understanding these two fundamental concepts is critical in choosing the correct insulation for your metal building. It identifies how effective the insulation will be against heat loss or gain, directly impacting energy efficiency.

Understanding Local Code Requirements for Metal Building Insulation

Clearly, adherence to local building codes can’t be overlooked, as they’re set to guarantee safety standards in construction. Insulation requirements, for instance, vary based on the location and purpose of the building. It’s important to check these codes before choosing your insulation type.

Firstly, for some regions with extreme temperatures, higher R-values (thermal resistance) might be required. The R-Value determines insulation’s ability to resist heat flow. Higher R-values mean greater insulating power.

Secondly, buildings serving as living spaces often come with stricter insulation requirements compared to storage or agriculture-related buildings. Therefore, keep in mind the intended use of the building.

Lastly, a Fire Resistance Rating (FRR) may be required for metal building insulation in certain localities. Insulation materials with appropriate FRR ensures the building is protected against the spread of fire.

Seeking advice from local building authorities or a professional builder can be helpful in understanding these requirements. Remember, conforming to local building codes isn’t just about compliance, it’s about creating a safer and more efficient building.

Determining the Amount of Insulation for Your Metal Building

Estimating the quantity of insulation needed is no small task. It’s primarily influenced by three factors: the local climate, the building’s purpose, and the regional energy code requirements.

Let’s begin with your local climate. In milder regions, a light layer of insulation might suffice, while colder climates require thicker insulation to offset heat loss. For instance, a workshop in sunny Arizona would need less insulation compared to a manufacturing plant in frosty Minnesota.

The building’s usage also plays a significant role. Spaces with lots of human activity or temperature-sensitive operations often demand more insulation. A storage facility may get by with minimal insulation, whereas a photography studio being used daily would benefit from more.

Additionally, your area might have specific energy code requirements regarding insulation levels, drawn up typically by local or regional governments. These codes are designed to promote energy efficiency and sustainable practices, so it’s vital you familiarize yourself with, and adhere to, these stipulations.

Remember, the correct amount of insulation can achieve the trifecta of climate control, energy efficiency, and operational savings in your metal building. Therefore, it’s crucial to assign due importance to this aspect right at the planning stage.

Most Common Metal Building Insulation Options

Navigating through the sea of insulation options for metal buildings, three commonly used types surface – spray foam, rigid board, and batt and blanket insulation.

Spray foam insulation, favored for its high R-value, conforms easily to any shape, making it perfect for irregular spaces. Additionally, its vapor and air barriers offer added protection against condensation, moisture, and heat transfer.

Rigid board insulation, composed of either fiberglass, polyurethane, or polystyrene, is renowned for its high insulating values and resistance to moisture. It’s an excellent choice for roofs and walls in commercial, industrial, and residential buildings.

Batt and blanket insulation—typically made of mineral wool, natural fibers, plastic, or fiberglass—is cost-effective, easy to install, and well-suited for walls and between beams. It’s a widely utilized choice for interior temperature control, but its lower R-value necessitates a supplemental vapor barrier to thwart condensation in a humid climate.

Exploring these three insulation types and their respective benefits can help choose the most suitable method for your metal building, taking into consideration the specific needs of your project including the local climate, code requirements, and budget.

Specifics of Spray Foam Insulation For Metal Buildings

Spray foam insulation comprises isocyanate and polyol resin, which, when combined, expand up to 60 times their liquid volume. This expansion enables the foam to fill every nook, crack, and cranny in a metal building, achieving distinctive coverage and a high level of thermal efficiency.

From an application perspective, spray foam can be installed faster compared to some other types of insulation, allowing a decrease in labor costs and potential disruption to work schedules. Additionally, the material can adhere to almost all surfaces, indulging the distinct shapes and structures ubiquitous in metal buildings.

The enhanced air sealing property of spray foam combats air leaks far better than conventional insulation products, fundamentally reducing energy costs for heating or cooling. This type of insulation is also moisture-resistant, significantly reducing the risk of condensation and related issues such as corrosion or mold formation inside your metal building.

Durability is another notable factor. Spray foam maintain its insulative properties over time, resulting in a one-time significant investment for long-term benefits, making it a choice worth considering for insulating metal structures.

Differences Between Open-cell and Closed-cell Spray Foam

Open-cell spray foam, as its name suggests, has tiny cells that aren’t fully enclosed. This gives the insulant a flexible, soft texture, and it expands once applied, useful for getting into small cracks and crevices. This type is more permeable to air and moisture than its counterpart, making it less suitable for environments with high humidity levels.

On the other hand, closed-cell foam features completely encapsulated cells, rendering it rigid and water-resistant. This denser option demonstrates a higher R-value per inch, resulting in superior thermal resistance. It also adds structural strength to a building, strengthens the structure and reduces air leakage considerably, making it a top contender for metal buildings.

These key differences inform the suitability of each type. A primary deciding factor is the specific requirements of your building project such as climate, desired energy efficiency, and budget, given the costlier nature of closed-cell foam.

Characteristics of Rigid Board Insulation For Metal Buildings

Rigid board insulation, typically made from materials like fiberglass, foam or polystyrene, offers a high R-value, between R-4 and R-8 per inch of thickness. This denotes excellent thermal resistance and therefore outstanding heat retaining properties. It’s often installed in large panels consisting of flat boards or fan-folded sheets.

Designed to withstand the most severe weather conditions, it is remarkably resistant to moisture and offers excellent dimensional stability. Notably, it lacks the buffering capacity that some other insulations employ, which can be beneficial in loud environments where noise control is a concern.

However, rigid board insulation requires a higher upfront investment than other options. The complexity of installation and the potential for thermal bridging, a phenomenon that allows heat to bypass the insulation through construction elements, also need to be considered. Its compatibility with specific design requirements must also be investigated, as it isn’t always the most flexible solution.

Used most frequently for insulating the flat metal roofs, rigid board insulation is often the go-to for projects where insulation thickness limitations come into play, providing optimal benefits in minimal space. This type of insulation is one of the most suitable for areas with extreme temperature variations.

Understanding Batt and Blanket Insulation For Metal Buildings

Batt and blanket insulation is often made from mineral wool, fiberglass or natural fibers. This type of insulation is beneficial due to its relative ease of installation and affordability. Since it comes in rolls or semi-rigid batts, it easily fits between common stud spacings in wall and ceiling cavities.

The effectiveness of batt or blanket insulation can be compromised if it is compressed or if gaps are left around obstructions. Precise cutting and fitting is necessary to avoid wastage and to ensure maximum protection. A vapor retarder is typically needed to prevent condensation, which could potentially rust the metal building’s exterior walls.

It’s important to note that while batts typically provide R-values ranging from 3 to 4 per inch depending on the thickness and material, these numbers can be variable and subject to changes based on installation quality. Therefore, hiring a professional with expertise in insulation installation might provide greater energy efficiency for your metal building in the long run.

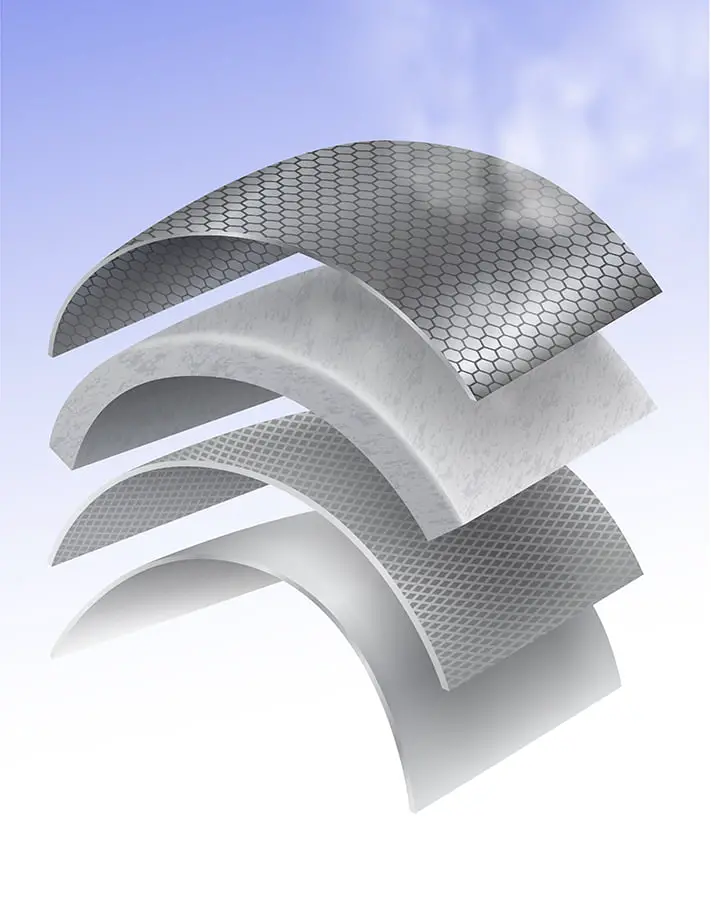

In built-up systems, two or more layers of insulation can be combined to increase the total R-value. Consider this for climates with extensive seasonal temperature variations. Also, safety precautions should be in place when handling fiberglass or mineral wool to prevent skin irritation or inhalation hazards.

Loose-fill Insulation For Metal Buildings: Utilization and R-value

Filled into cavities or blown onto surfaces, loose-fill insulation is versatile in its application. Manufactured from small particles of fiber, foam, or other materials, it is often used in irregularly shaped areas and around obstacles.

One key benefit of loose-fill insulation is its higher R-value per inch, which can reach up to R-3.8, depending upon the material. This makes it a top-ranking option in terms of thermal resistance, ensuring the metal building remains comfortable in varied weather conditions.

Additionally, it proves ideal for retrofits and areas where other insulation types may not fit properly. Thus, loose-fill insulation offers customization to work in a variety of spaces, aiding temperature control even in hard-to-reach areas.

Despite its effectiveness, it may settle over time and can be a little challenging to install when compared to other insulation types. Oversight on professional installation and maintenance can ensure it delivers the expected performance over time.

The Efficiency Of Foil Bubble Insulation For Metal Buildings

Foil bubble insulation, often used for its radiant heat blocking capabilities, could be a practical choice for metal buildings. In essence, its structure comprises of reflective foil on both sides with a layer of polyethylene bubbles trapped between them.

Here are some key details:

- Radiant Heat Barrier: The shiny foil inhibits the transfer of radiant heat, keeping the interior cool in high-temperature climates.

- R-Value and Thickness: Typically, it offers an R-value of 3.7 per inch of thickness. Remember, higher the R-value, better the insulation properties.

- Easy Installation: Foil bubble insulation is lightweight and quite simple to install, significantly cutting down labor costs and efforts.

- Durability: The materials resist growth of fungi or mold, and won’t crumble or disintegrate over time, ensuring longevity.

- Cost-effective: Despite its efficiency, it’s usually more affordable compared to other high-performing insulation materials.

However, it’s essential to confirm whether this insulation is appropriate, depending on the specifics of the construction and climatic conditions. It’s not universally suitable for all metal buildings, but in the right circumstances, it can be a highly efficient and economical choice.

Considerations When Choosing Insulation: Condensation, Temperature Control, and Workability

During the decision-making process, condensation control plays a critical role. An inability to effectively manage this can lead to rust and deterioration of the metal structure. When planning for insulation, ensure you opt for materials that combine thermal resistance with an effective vapor barrier.

Temperature control is equally imperative; maintaining a stable internal environment, especially for climate-sensitive operations, can be crucial. Be on the lookout for insulation with high R-values for optimal thermal performance.

The workability of the insulation material is another factor to mull over. Something like spray foam, for instance, settles tightly into crevices and corners, providing a comprehensive barrier against heat and cold. However, it requires professional application and has a higher upfront cost compared to alternatives like batt or loose-fill insulation, which are more DIY-friendly.

Moreover, consider fluctuating weather patterns in your region, expected energy savings, and the planned use of the building. These elements will collectively aid in the effective determination of insulation type, thickness, and installation method.

Incorporation of Facing and Liner Panels in Insulation for Metal Buildings

Facing, often made from aluminum foil or vinyl, is chiefly employed to provide a barrier against water vapor, creating an avenue for its escape. When installed in combination with an insulation layer, a facer can significantly boost the overall R-value of the material. Furthermore, certain types of facing also contribute to enhancing the aesthetics of the metal building’s interior.

Liner panels, on the other hand, are typically used in conjunction with fiberglass or spray foam insulation. They essentially serve as cladding to encapsulate the insulation material, providing an additional layer of protection against external elements. Liner panels also offer a clean, finished look to the building’s interior.

Key factors to consider when incorporating these elements include:

- Type of insulation: Different insulation materials require specific types of facing and liner panels.

- Climate considerations: In humid regions, emphasis should be placed on using facers with high moisture resistance.

- Fire Safety: Flame-resistant facers and liner panels are ideal for metal buildings used for commercial or industrial purposes.

- Durability: Ensure the chosen facer and liner panel can withstand the environmental conditions of the building’s location.

Incorporating facing and liner panels in your insulation plan can not only improve your metal building’s energy efficiency but also enhance its overall appearance and durability.

FAQ

What kind of insulation do you use on a steel building?

The most effective insulation for a steel building is typically closed-cell spray foam due to its ease of installation, built-in vapor barrier, and ability to create an impenetrable airtight seal.

What is the best R-value for insulation a metal building?

The best R-value for insulating a metal building is R-38, achieved by using a twelve-inch thick double layer of high R-value fiberglass batt insulation.

How thick should insulation be for a metal building?

The recommended insulation thickness for a metal building is 4-inches, suitable for achieving a 13 R-value, whereas thicker insulation is often reserved for roof applications.

What is the cheapest way to insulate an existing metal building?

The cheapest way to insulate an existing metal building is by using fiberglass batt insulation due to its widespread availability, affordability, and ease of installation.

How does the climate impact the choice of insulation for metal buildings?

The choice of insulation for metal buildings is significantly impacted by the climate as colder regions necessitate thicker insulation for heat retention, while in hotter areas, reflective insulation is preferred to keep the building cool.

What role does insulation’s resistance to moisture play in the purpose of metal building applications?

Insulation’s resistance to moisture plays a significant role in metal building applications by preventing condensation, fostering energy efficiency, and safeguarding against corrosion, thus extending the structure’s lifespan.

How does the purpose of the metal building influence the selection of insulation type?

The purpose of the metal building strongly influences the selection of insulation type as different purposes require varying levels of thermal resistance, soundproofing, and condensation control.

Recap